The ERW tube mill is a cornerstone of modern pipe manufacturing. It produces welded tubes using electric resistance welding. This method ensures strong, durable pipes for global industries. Companies like SANSO have refined these mills for better performance. The demand for efficient pipe production keeps the erw tube mill relevant.

This article dives into the erw tube mill's workings. We will look at its components and uses. The goal is to provide practical insights for professionals. From construction to automotive sectors, the erw tube mill plays a key role. Let's explore its impact on manufacturing.

What is an ERW Tube Mill?

An ERW tube mill is a machine that makes pipes. It uses electric resistance welding to join steel strips. The process involves passing strips through forming rolls. Then, edges are heated and pressed together. This creates a seamless weld without filler materials.

The erw tube mill is known for its speed. It can produce pipes continuously. This makes it ideal for high-volume projects. The quality of pipes from an erw tube mill meets international standards. Industries rely on it for consistent output.

Key Components of an ERW Tube Mill

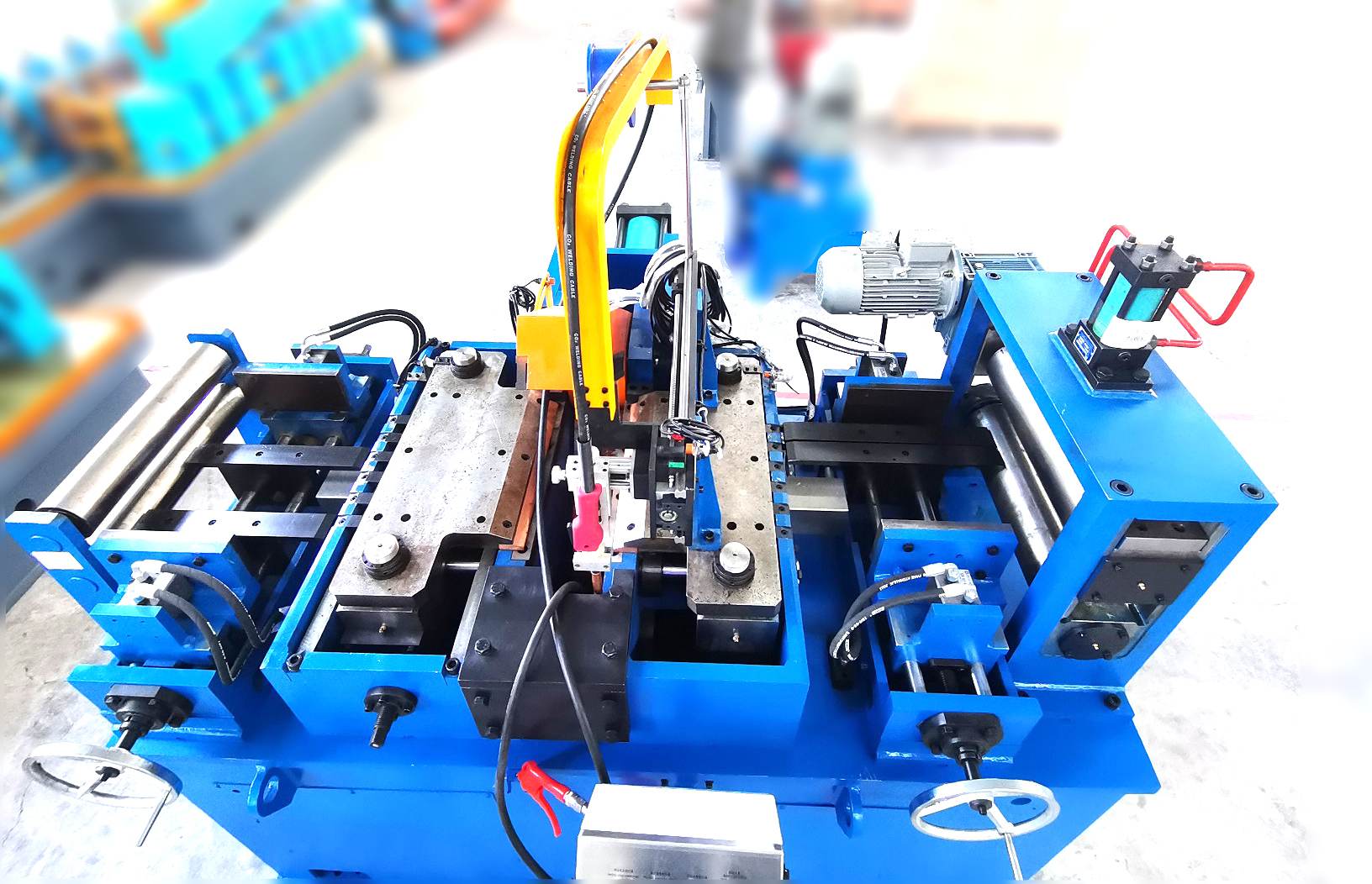

An erw tube mill has several vital parts. The uncoiler feeds steel strips into the system. Forming rolls shape the strips into a tube. The welding unit uses electric current to fuse edges. Sizing rolls adjust the pipe dimensions. Finally, a cutting unit sections the pipe to length.

Each component must work in harmony. Precision in these parts ensures pipe quality. Modern erw tube mills include automation. This reduces human error. Brands like SANSO integrate advanced controls. Their mills offer real-time monitoring for better efficiency.

Working Principle of an ERW Tube Mill

The working principle starts with coil preparation. Steel coils are loaded onto the uncoiler. Strips are straightened and fed into forming rolls. These rolls gradually curve the strip into a cylindrical shape. As edges meet, they pass through welding electrodes.

Electric resistance heats the edges. Pressure is applied to forge a weld. The weld is then cooled and smoothed. Sizing rolls calibrate the pipe diameter. The pipe is cut and inspected. This process in an erw tube mill is fast and reliable. It minimizes material waste.

Applications of ERW Tube Mills in Industry

ERW tube mills serve diverse sectors. Their ability to produce various pipe sizes makes them versatile. From small tubing to large conduits, the erw tube mill handles it all. The welded pipes are used in infrastructure and machinery. This highlights the erw tube mill's importance.

Pipes from an erw tube mill are strong and lightweight. They resist corrosion well. This suits them for harsh environments. The manufacturing world depends on the erw tube mill for supply chain stability.

ERW Tube Mills in Construction

In construction, erw tube mills produce structural pipes. These pipes form building frames and supports. They are also used in scaffolding and fencing. The erw tube mill ensures pipes meet safety codes. Consistency in dimensions is crucial here.

Construction projects often need custom pipe sizes. An erw tube mill can be adjusted for this. Speed is another benefit. It helps meet tight deadlines. The erw tube mill thus supports urban development globally.

ERW Tube Mills in the Automotive Industry

The automotive industry uses pipes for exhaust systems and frames. An erw tube mill makes these pipes with high precision. The welding process creates leak-proof joints. This is vital for vehicle safety and performance.

Automakers seek lightweight materials. Pipes from an erw tube mill reduce vehicle weight. This improves fuel efficiency. The erw tube mill also supports electric vehicle production. It makes battery casing tubes. SANSO's mills are used in this sector for their reliability.

Benefits of Using an ERW Tube Mill

Investing in an erw tube mill offers many advantages. It boosts production rates compared to other methods. The electric resistance welding is energy-efficient. This lowers operational costs. The erw tube mill also produces high-quality welds.

Pipes from an erw tube mill have uniform strength. They require minimal post-weld processing. This saves time and resources. The erw tube mill is adaptable to different materials. It works with carbon steel, stainless steel, and alloys.

Efficiency of ERW Tube Mills

Efficiency is a hallmark of the erw tube mill. It operates continuously with little downtime. Automation reduces labor needs. The erw tube mill can produce pipes at speeds over 100 meters per minute. This throughput meets high demand.

Modern erw tube mills include quick-change tools. This allows for fast size adjustments. Less setup time means more productivity. The erw tube mill also integrates with quality checks. Sensors detect defects early. This minimizes waste.

Cost-Effectiveness of ERW Tube Mills

An erw tube mill is cost-effective in the long run. Initial investment pays off through reduced production costs. The welding process uses no consumables like gas or filler. This cuts material expenses. The erw tube mill also has low maintenance needs.

Energy consumption is optimized. Newer models from SANSO feature energy-saving modes. The erw tube mill's durability ensures years of service. This makes it a smart choice for manufacturers. It helps them stay competitive.

Choosing the Right ERW Tube Mill

Selecting an erw tube mill requires careful thought. Factors like production capacity and pipe specs matter. The erw tube mill must match your factory's needs. Consider the material types you'll process. Also, look at available space and budget.

An erw tube mill with modern controls is preferable. It offers better precision. After-sales support is key. Brands with good service ensure smooth operations. The erw tube mill should comply with industry standards. This guarantees product acceptance.

Factors to Consider When Buying an ERW Tube Mill

First, assess your output requirements. An erw tube mill's speed and size range should fit your goals. Check the welding technology. Some mills offer high-frequency welding for better quality. The erw tube mill's automation level affects labor costs.

Inspect the build quality. Robust frames reduce vibration. This improves pipe accuracy. The erw tube mill's energy efficiency ratings matter. They impact running costs. Also, consider scalability. Can the erw tube mill be upgraded later? This future-proofs your investment.

SANSO's Innovations in ERW Tube Mills

SANSO is a known brand in pipe mill manufacturing. They focus on improving the erw tube mill. Their mills feature advanced servo drives. These enhance control and reduce waste. SANSO's erw tube mill models are user-friendly. They come with touch-screen interfaces.

SANSO also emphasizes sustainability. Their erw tube mill designs use recycled materials. They offer training for operators. This ensures optimal use of the erw tube mill. SANSO's research leads to quieter, safer mills. Their contributions push the erw tube mill industry forward.

In summary, the erw tube mill is vital for pipe production. It combines speed with quality. Applications span from construction to automotive fields. Benefits include efficiency and cost savings. Choosing the right erw tube mill involves evaluating needs and brands.

SANSO stands out for innovation in this space. Their erw tube mill solutions address modern challenges. As technology evolves, the erw tube mill will continue to shape manufacturing. Investing in a reliable erw tube mill is a step toward growth.

Frequently Asked Questions (FAQs)

Q1: What is an ERW tube mill used for?

A1: An ERW tube mill is used to manufacture welded pipes through electric resistance welding. It produces pipes for industries like construction, automotive, and energy. The erw tube mill ensures high-speed production with consistent quality.

Q2: How does an ERW tube mill differ from other pipe mills?

A2: An ERW tube mill specifically uses electric resistance welding, which heats pipe edges without filler material. This makes it faster and more cost-effective than methods like seamless pipe production. The erw tube mill is ideal for high-volume output.

Q3: What materials can be processed in an ERW tube mill?

A3: An ERW tube mill typically processes carbon steel, stainless steel, and low-alloy steels. It can handle various thicknesses and widths. The erw tube mill's flexibility allows for custom pipe production based on material properties.

Q4: What are the maintenance requirements for an ERW tube mill?

A4: Maintaining an ERW tube mill involves regular cleaning, lubrication, and inspection of rolls and welding units. Parts like electrodes may need replacement over time. Proper upkeep ensures the erw tube mill operates efficiently and extends its lifespan.

Q5: How does SANSO enhance ERW tube mill technology?

A5: SANSO enhances ERW tube mill technology by integrating automation, energy-efficient systems, and user-friendly controls. Their mills feature real-time monitoring and quick-change tools. SANSO's innovations make the erw tube mill more productive and sustainable for manufacturers.