The welded tube manufacturing industry relies on precise machinery to transform raw materials into high-quality products. Among these, coil slitting equipment plays a critical role in processing metal coils into narrow strips. This process is fundamental for feeding tube mills with accurate material dimensions. Brands like SANSO have developed advanced systems to meet global demands for efficiency and precision.

Coil slitting equipment is used to cut wide metal coils into narrower strips. These strips are then used in various manufacturing processes, including welded tube production. The equipment ensures consistent width and edge quality, which is vital for downstream operations.

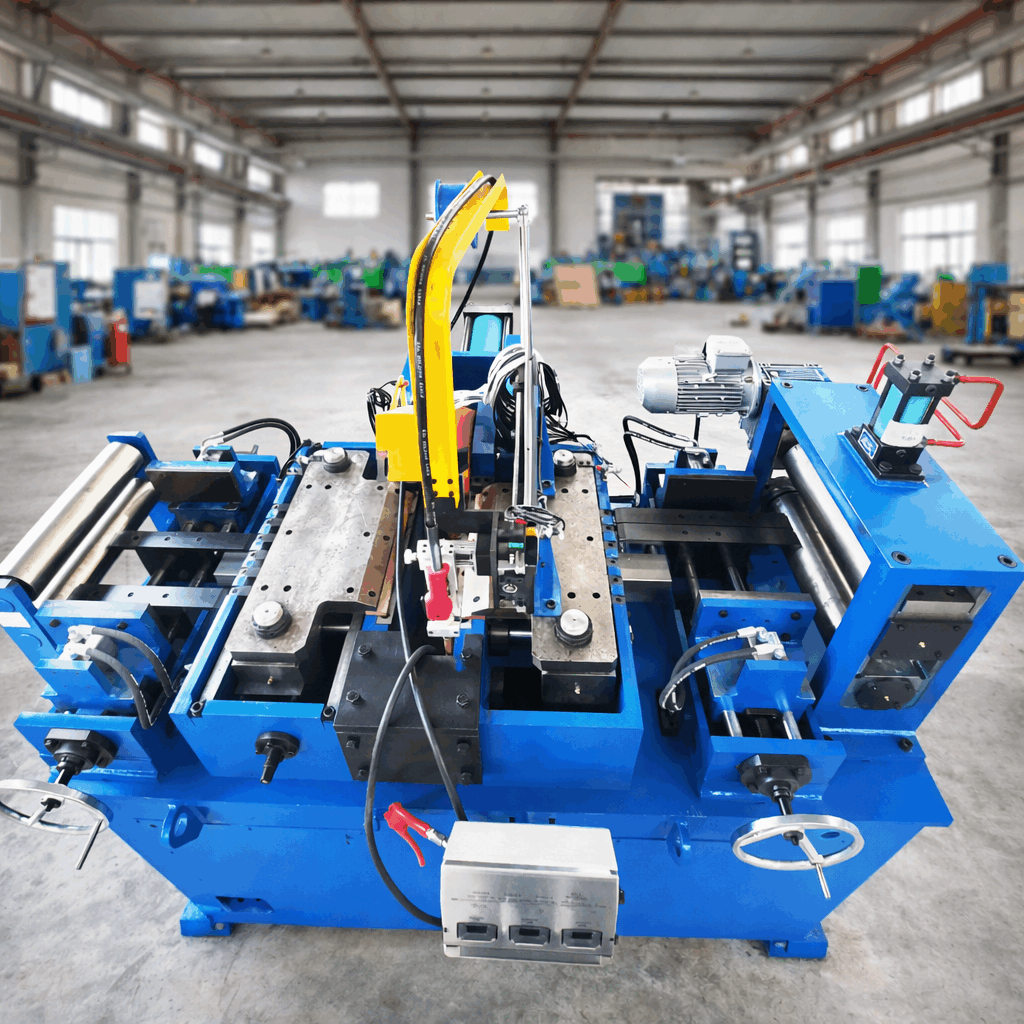

A typical slitting line consists of several parts that work together seamlessly. Understanding these components helps in optimizing performance.

Uncoiler: This unit feeds the metal coil into the system. It handles different coil weights and diameters.

Slitter Head: Equipped with rotary knives, it performs the actual cutting. Precision here affects strip quality.

Scrap Winders: These collect edge trim scrap, promoting material efficiency and safety.

Recoiler: It rewinds the slit strips into smaller coils for further processing.

Modern coil slitting equipment often includes automation features. These reduce manual intervention and improve speed. In welded tube milling, consistent strip dimensions from slitting lines ensure smooth tube formation.

The international welded tube industry uses slit strips as feedstock for tube mills. Accurate slitting prevents defects in tubes, such as welding inconsistencies or dimensional errors. This equipment is essential for producing pipes used in construction, automotive, and energy sectors.

Slitting lines are often paired with tube mills to create a continuous production flow. Strips from the coil slitting equipment are fed directly into forming and welding stations. This integration minimizes material handling and reduces waste.

It allows for just-in-time material supply, lowering inventory costs.

Consistent strip quality enhances the welding process in tube mills.

Advanced systems from SANSO offer compatibility with various mill setups.

Different metals require specific slitting approaches. Steel, aluminum, and stainless steel are common in tube manufacturing. The equipment must adjust knife settings and tension controls accordingly.

Proper material handling prevents edge burrs and camber. This ensures that strips meet tight tolerances for tube production. High-quality coil slitting equipment can process a range of thicknesses and strengths.

Upgrading to contemporary slitting technology offers numerous advantages. These benefits impact productivity, cost, and product quality in welded tube manufacturing.

Precise cutting reduces material waste and improves yield. Digital controls maintain strip width within microns. This accuracy is crucial for meeting international standards in tube dimensions.

Laser-guided systems enhance alignment and cutting consistency.

Automated knife positioning adapts to different coil specifications.

Reliable coil slitting equipment from brands like SANSO ensures repeatable results. This supports high-volume production without compromising quality.

Fast slitting lines reduce cycle times, allowing more coils to be processed daily. Features like quick knife changes and automated threading minimize downtime.

Efficient scrap removal systems keep the line clean and safe. This contributes to a smoother workflow in tube milling operations. Investing in robust coil slitting equipment can lead to significant cost savings over time.

Selecting appropriate slitting machinery requires careful evaluation. Factors like production volume, material types, and space constraints must be considered. This decision affects long-term operational success.

When assessing slitting equipment, focus on technical details that match your requirements. These specifications determine performance and compatibility.

Coil Width and Thickness Capacity: Ensure the machine handles your typical material sizes.

Slitting Speed: Measured in meters per minute, it influences output rates.

Knife Type: Rotary knives versus drag knives; choice depends on material hardness.

Control System: User-friendly interfaces with programmable settings improve operation.

Consulting with experts from SANSO can provide insights into optimal configurations. Their experience in welded tube milling helps tailor solutions.

Regular maintenance extends the lifespan of slitting equipment. Simple practices can prevent breakdowns and ensure consistent performance.

Schedule routine inspections of knives and bearings. Keep the line clean from metal debris. Train operators on proper handling and safety protocols. Well-maintained coil slitting equipment reduces unexpected downtime in tube production.

Coil slitting equipment is indispensable in the international welded tube manufacturing sector. It provides the precision and efficiency needed for high-quality tube production. As technology advances, slitting lines become more automated and reliable. Companies like SANSO continue to innovate, offering solutions that enhance productivity. Investing in modern coil slitting equipment is a strategic move for any tube mill aiming to stay competitive.

Q1: What is the primary function of coil slitting equipment in tube manufacturing?

A1: The main function is to cut wide metal coils into narrow strips. These strips serve as feedstock for tube mills, ensuring consistent material dimensions for welding and forming processes.

Q2: How does coil slitting equipment improve productivity?

A2: It speeds up material processing by enabling fast, precise cutting. Automated features reduce manual labor and downtime, allowing higher output in welded tube production.

Q3: What materials can be processed using coil slitting equipment?

A3: This equipment can handle various metals, including mild steel, stainless steel, aluminum, and copper. The choice depends on knife configuration and tension settings.

Q4: How often should maintenance be performed on slitting lines?

A4: Regular maintenance is recommended monthly or based on usage. Key tasks include knife sharpening, lubrication, and inspection of mechanical parts to prevent failures.

Q5: Why is precision important in coil slitting for tube mills?

A5: Precision ensures slit strips have uniform width and clean edges. This consistency is critical for proper tube formation and welding, reducing defects and material waste.