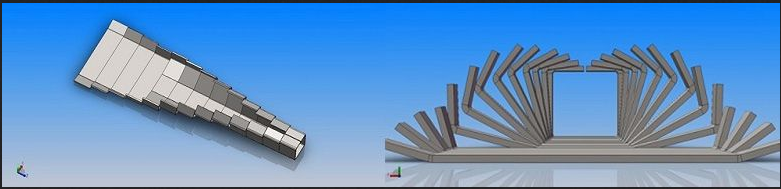

Forming Principle: A direct square pipe mill gradually forms a strip of specific width into a square or rectangular tube of the corresponding specification. This process is completely different from the traditional method of reshaping a round tube into a square or rectangular one.

The process begins with the first bend (the top side of the square/rectangular tube) being solid-bent to an 80-degree angle. Next, the second bend (the side wall of the square/rectangular tube) is bent to approximately a 65-degree angle. In the third step, the top and side of the steel strip are simultaneously air-bent to an 86-degree angle. The formed tube then passes through welding guides, followed by welding, squeezing, and ironing to complete the welded

Finally, the tube's external dimensions and corner radius are precisely calibrated, and any longitudinal curvature (bow) in the finished tube is eliminated by a Turkish head (straightening unit).

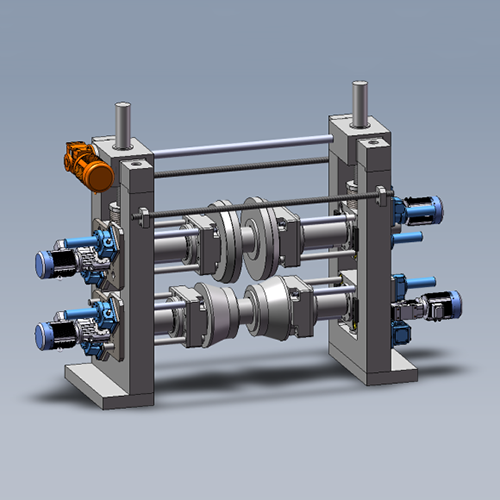

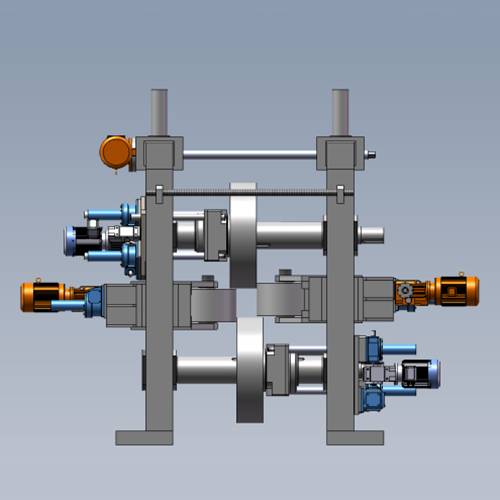

The stand of DFS tube mill is more complicated than that of conventional tube mill.

Besides the roller shaft and roller block with bearing, the roller stand assembly is composed of .segment roller installed the moveable block, servo motor or AC motor with reducer and steering box ,screw jack.and screw rod etc. Which ensure the roller adjustment accuracy

1.General information :the roller is position is adjusted through reducer and screw jack by the PLC-driven servo motor. The operator just input the tube’s size on the touch screen when change the tube size from one to another ,the roller’s position can be adjusted by the the PLC-driven servo motor automatically.

2.Detailed description :

This system is fitted with the most advanced PLC control and digital control technologies. The PLC is selected from the Siemens S7-1500 series (Germany), known for its powerful functionality and high reliability. Roll positioning adjustment is made by the SIEMENS V90 PN servo system, with multi-turn absolute encoders forming positional axes to enable rapid, automatic, and precise roll adjustment.

The entire system utilizes the industrial Ethernet PROFINET communication protocol, ensuring fast, stable, and reliable operation of all equipment. The operator touchscreen employs recipe functionality to enable quick parameter settings for roll positions of various tube specifications. A handheld mobile operating panel allows for manual and automatic adjustment of roll positions at close range.

During product specification changes, the roller is adjusted automatically, reducing downtime to approximately 30 minutes. The load distribution of each roller’s motor, real-time roller positions, and equipment fault information can all be queried on HMI of main console .

This not only greatly facilitates timely monitoring of production conditions by operators and management but also significantly shortens troubleshooting time for maintenance personnel, ensuring stable and efficient pipe production.

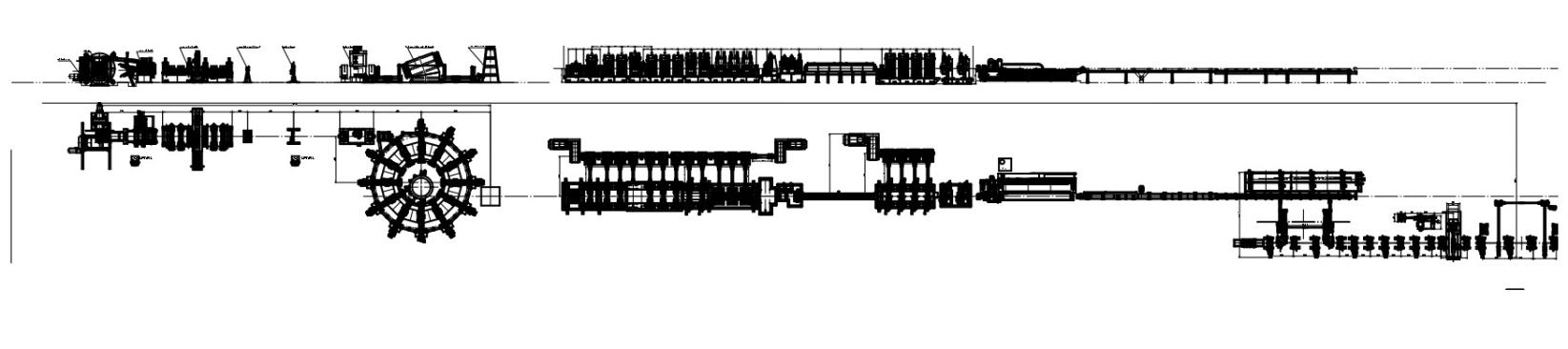

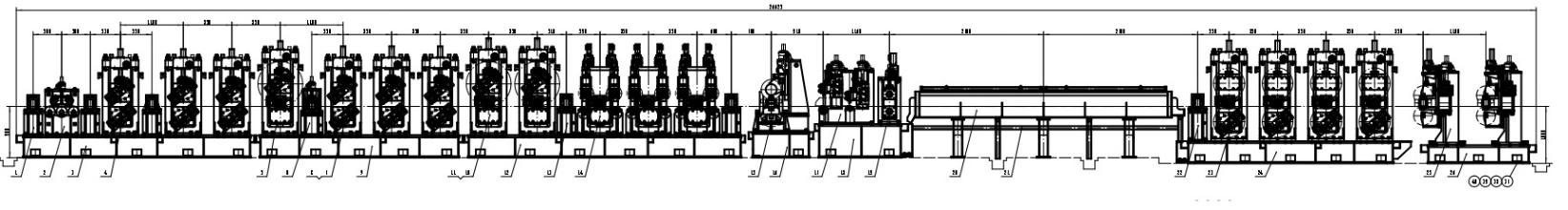

Strip coil→ Uncoiling →coil peeler → pinch & Leveling →Shearing and butt welding → accumulator → Forming → Welding → bead remover →water cooling →Sizing → Turks head → Flying saw cutting → Tube collecting

1.The saving the roller cost .

In the conventional welded tube mill, one complete set roller only manufacture one size tube . but for the direct forming square tube mill ,One complete set roller can manufacture 12--15 square or rectangular tubes. This tremendously save the roller divestment and inventory.

2.Extreme reduction of roller set up time .

Thanks to the automatic roller adjustment of DFS tube mill, it needs only 30 minutes to change one size to another .

Take 100X100mm tube as an example.

For the conventional welded tube mill , it needs 6 hours to change the rollers by 5 workers ,

For DFS welded tube mill, it only needs 30 minutes to adjust roller position

This tremendously save set up time ,so that the productivity is enhanced.

3.Save the raw material .

Thanks to the forming principal of DFS welded tube mill and ductility of steel strip,2%--4% steel strip width can be saved for the same profile production,compare the conventional tube mill.

Take100X100X2mm square tube as an example ,

Some 408.4X2mm strip is needed to manufacture the 100X100X2mm tube by conventional welded tube mill.

However,some 393.72X2mm strip is needed to manufacture the 100X100X2mm tube by direct forming square tube mill.

4.Completely meet the requirement of multi-product small batch production .

The dealer and customers do not want to carry a lot of inventory of steel tube they may not use right now , so that minimize the use of working capital as much as possible. This requires the manufacturer of steel tube to manufacture the tube quickly when they place an gotta-have-it now order.

Thanks to the automatic roller adjustment of DFS tube mill within 30 minutes, the manufacturer the tubes customer need urgently.

| MODEL | PROFILE SIZE RANGE | THICKNESS | SPEED |

|---|---|---|---|

| DFS50 | 20X20--50X50MM | 0.8--3.0mm | 20-80m/min |

| DFS100 | 30×30-100×100mm | 1.0mm-5.0mm | 20-80m/min |

| DFS150 | 70×70-150×150mm | 1.5mm-6.0mm | 20-50m/min |

| DFS200 | 80×80-200×200mm | 2.0mm-8.0mm | 20-40m/min |

| DFS250 | 100×100-250×250mm | 3.0mm-10mm | 10-40m/min |

| DFS300 | 120×120-300×300mm | 4.0mm-12mm | 10-40m/min |

| DFS400 | 180×180-400×400mm | 5.0mm-14mm | 10-30m/min |

| DFS500 | 250×250-500×500mm | 5.0mm-20mm | 10-25m/min |