In the world of metalworking and tube production, few machines are as critical as the ERW pipe making machine. This equipment forms the backbone of countless industrial operations, creating the pipes that build our infrastructure, vehicles, and appliances.

If you're sourcing machinery or simply want to understand modern manufacturing, knowing about the ERW (Electric Resistance Welded) pipe making machine is essential. We’ll break down its operation, benefits, and what makes a reliable model. Companies like SANSO have become notable names in this field by engineering robust and efficient versions of this machine.

This article provides a clear, practical look at the technology without oversimplifying its complexities.

Understanding the ERW Pipe Making Machine

At its core, an ERW pipe making machine is a continuous production line. It transforms flat steel coils into rounded, welded pipes of specific diameters and thicknesses. The "Electric Resistance Welding" part is the key differentiator.

This method uses electrical current and pressure to create a forge weld along the pipe's seam. Unlike older methods, it doesn't require a welding filler material. The result is a strong, clean, and consistent weld.

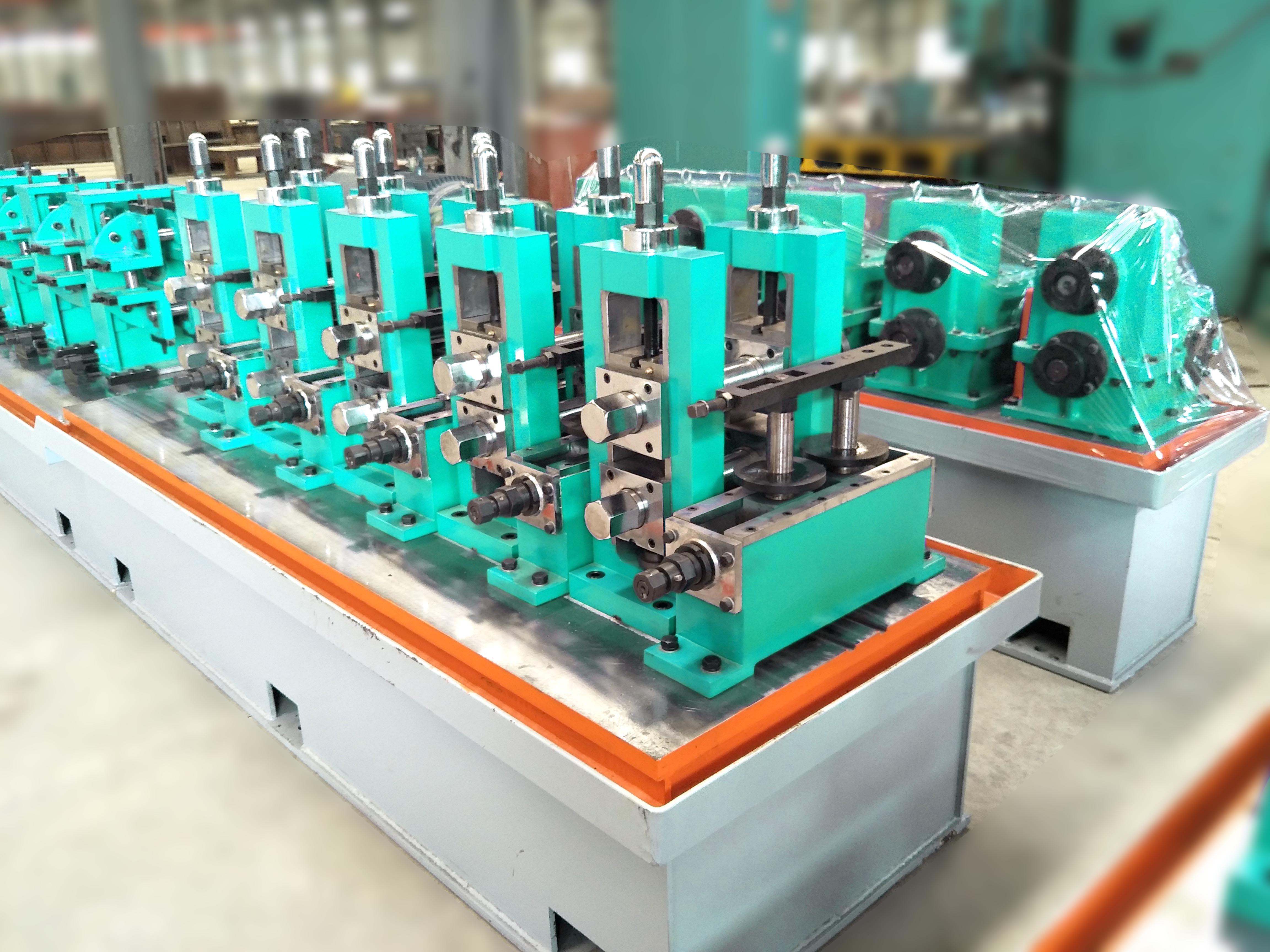

The entire ERW pipe making machine line is a symphony of coordinated components. Each section has a precise role, from uncoiling the raw material to cutting the finished product to length.

Key Components of the Production Line

A modern ERW pipe making machine is not a single unit but a sequence of stations. Here are the major parts:

Pay-off & Decoiler: This holds the heavy coil of steel strip (skelp) and feeds it into the line in a controlled manner.

Flattener & Edge Trimmer: As the name suggests, this section flattens any coil curvature and trims the strip edges to ensure clean, straight sides for a perfect weld.

Forming Section: This is the heart of the shaping process. A series of precisely machined roller cages gradually curve the flat strip into a circular tube shape. The skill in mill design is paramount here.

Welding Unit: The open-seamed tube passes by copper electrodes or an induction coil. A high-frequency electrical current is applied, heating the edges to a plastic state. Squeeze rolls then forge them together under high pressure to form the weld.

Sizing Section: After welding, the pipe is not perfectly round. Another set of calibrated rolls cold-works the pipe to achieve its final, precise outer diameter and roundness.

Cutting Unit: A flying saw or similar cutter moves with the running pipe and cuts it to predetermined lengths without stopping the production line.

Run-out Table: This section collects and transfers the finished pipes for bundling, inspection, or further processing.

Why Choose an ERW Pipe Making Machine?

Manufacturers invest in an ERW pipe making machine for compelling reasons. The advantages over seamless or other welded pipe processes are significant in many market segments.

First is production speed. An ERW line can run continuously at high speeds, often exceeding 100 meters per minute. This translates into tremendous output volumes, making it highly cost-effective for large orders.

Second is material efficiency. The process starts with a coiled strip, minimizing waste. The welding itself adds no extra material, keeping the seam neat and internal bore smooth.

Third is versatility. With quick roll changes, a single ERW pipe making machine can produce a range of diameters and wall thicknesses. This flexibility is crucial for job shops serving multiple clients.

The weld quality is excellent for most applications. Modern high-frequency welding produces a bond often as strong as the parent metal itself. This reliability is why ERW pipes are trusted in structural and mechanical uses.

Primary Industrial Applications

Pipes from an ERW pipe making machine are everywhere. Their applications define modern industry.

Construction & Infrastructure: This is the largest market. ERW pipes are used for scaffolding, structural frames, fencing, water and gas conveyance in buildings, and piling.

Automotive: The automotive industry uses ERW tubes for chassis components, roll cages, shock absorber housings, and various structural parts. The balance of strength and weight is key.

Furniture & Appliances: Look at any chair frame, bed frame, or the inner structure of large appliances. The aesthetic finish and consistent dimensions from a good ERW pipe making machine are ideal here.

Mechanical Engineering: Hydraulic cylinders, conveyor rollers, and machinery guards often start as ERW tubing. The smooth interior surface and good tolerances are necessary for these precision applications.

Selecting a Reliable ERW Pipe Making Machine Supplier

Buying an ERW pipe making machine is a major capital investment. Choosing the right supplier is as important as choosing the right specifications. You need a partner, not just a vendor.

Look for a supplier with proven experience. Ask for client references and, if possible, visit a factory where their machine is running. Seeing an ERW pipe making machine in operation tells you more than any brochure.

Examine the quality of components. Are the forming rolls made from high-grade, wear-resistant steel? Is the electrical system from a reputable brand like Siemens or Schneider? The durability of these parts dictates your uptime.

Consider technological support. Does the supplier offer comprehensive training for your operators and maintenance staff? Will they provide detailed manuals and schematics? Post-sales service and spare parts availability are non-negotiable.

Some manufacturers, like SANSO, have built a reputation by focusing on these areas. They offer a balance of robust mechanical design with user-friendly digital controls. A brand that invests in R&D to improve welding stability and energy efficiency is often a safer bet for the long term.

Key Specifications to Consider

When evaluating an ERW pipe making machine, you must match it to your product needs.

Pipe Range: Define the minimum and maximum outer diameter (OD) and wall thickness you need to produce. Ensure the machine is capable across this entire range.

Material Grade: What steel grades will you process? Mild steel, high-tensile steel, or low-alloy steels? The machine's power and roll strength must be suited to your materials.

Line Speed: Measured in meters per minute, this dictates your potential output. Balance your required daily tonnage with your budget, as higher speeds increase cost.

Welding Frequency: High-Frequency (HF) contact or induction welding is the modern standard. HF welding generally offers better quality and stability, especially for thinner walls and critical applications.

Automation Level: Basic lines require more manual intervention. Advanced lines feature automatic gauge control, laser weld tracking, and computerized fault diagnostics. This affects labor costs and consistency.

The Role of Technology and Future Trends

The basic principle of the ERW pipe making machine remains, but the technology around it evolves rapidly. Modern lines are becoming smarter and more connected.

Integration of IoT sensors allows for real-time monitoring of weld temperature, roll pressure, and motor load. This data can predict maintenance needs before a breakdown occurs, maximizing productivity.

Advanced non-destructive testing (NDT) systems, like ultrasonic or eddy current testing, are now often integrated directly into the line. This allows for 100% inspection of the weld seam, ensuring every piece of pipe meets quality standards.

Energy efficiency is a major focus. Newer designs from proactive manufacturers incorporate regenerative drives and optimized power supplies for the welder, significantly reducing the electrical operating cost of the ERW pipe making machine.

Looking ahead, the demand for flexibility will grow. Manufacturers will seek machines that can switch between product sizes faster and handle a broader mix of small-batch orders. Suppliers that can deliver this agility, like SANSO with their quick-change roll systems, will stay ahead.

In conclusion, the ERW pipe making machine is a sophisticated and indispensable piece of industrial equipment. Its ability to produce high-quality welded tube at high speed and with great material economy ensures its continued dominance in the market.

Success with this technology depends on understanding the process, clearly defining your needs, and partnering with a competent and reliable supplier. Whether you are a large mill or a growing fabricator, investing time in selecting the right ERW pipe making machine, from trusted brands in the space like SANSO, is the first step toward building a profitable and sustainable production operation.

Frequently Asked Questions About ERW Pipe Making Machines

Q1: What is the main difference between ERW and seamless pipe making?

A1: An ERW pipe making machine creates a weld along the seam of a formed strip. Seamless pipe is made by piercing a solid billet, so it has no welded seam. ERW is generally more cost-effective for high volumes and common sizes, while seamless is used for higher pressures and more critical applications.

Q2: What kind of steel can I run on an ERW machine?

A2: Most common ERW pipe making machines are designed for low-carbon ("mild") steel and some low-alloy steels. Some advanced mills can also handle higher strength steels. The specific grade affects the required welding power and roll pressure settings.

Q3: How do I ensure the weld quality is consistent?

A3: Consistency comes from machine stability and process control. A well-maintained ERW pipe making machine with precise edge preparation, stable HF current, and consistent squeeze roll pressure is vital. Integrating inline NDT inspection provides immediate feedback and quality assurance.

Q4: How often does an ERW machine require major maintenance?

A4: Regular daily and weekly lubrication and inspection are crucial. Major overhauls, such as replacing forming rolls or rebuilding gearboxes, depend on usage but might be needed every few years. Choosing a machine with accessible components, like those from SANSO, simplifies maintenance and reduces downtime.

Q5: Can one machine produce both round and square pipes?

A5: A standard ERW pipe making machine is designed for round tubes. To produce square or rectangular hollow sections (RHS), you need an additional section called a "tube mill" or "roll forming line" downstream, which shapes the round welded pipe into a square profile. Some integrated lines offer this capability.