In the demanding world of international welded tube and pipe manufacturing, efficiency and precision are non-negotiable. The cutting stage is critical, defining the final product's quality. Here, the choice of cutting tool is paramount. For many milling and cut-off applications, the high speed steel cutting blade remains a fundamental and versatile solution. Balancing durability, performance, and cost-effectiveness, these blades are workhorses in pipe mills worldwide. Brands like SANSO have refined this technology, offering reliable options for various production needs. Understanding their proper application and selection is key to optimizing your milling operations.

A high speed steel cutting blade is a circular saw blade made from high-speed steel (HSS), a specialized alloy steel. It's designed to withstand high temperatures generated during cutting without losing its hardness, a property known as "red hardness." This makes it superior to traditional carbon steel tools for faster cutting operations.

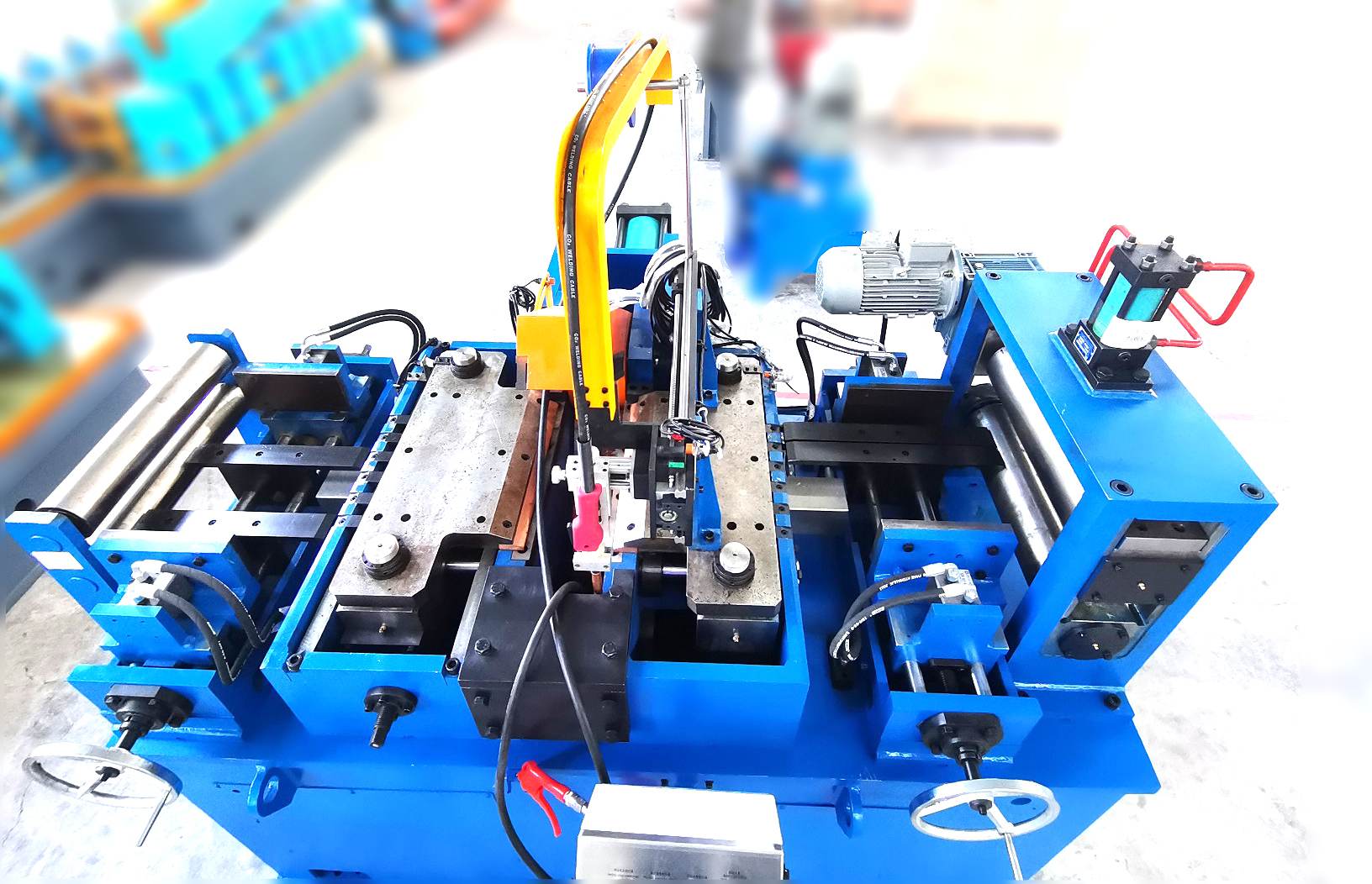

In tube and pipe milling lines, these blades are commonly mounted on stationary or traveling cut-off saws. They cleanly sever welded pipe to length after the forming and welding stages. The high speed steel cutting blade must handle various materials, from carbon steel to softer non-ferrous pipes, making it a flexible tool for many manufacturers.

Selecting the correct blade is not a one-size-fits-all decision. Several factors directly impact performance and blade life.

First, consider the material being cut. While HSS is versatile, blade tooth geometry and coating vary. For thin-walled tubing, a blade with more teeth provides a smoother cut. For thicker-walled pipe, fewer teeth with a more aggressive hook angle is better for chip clearance.

Blade diameter and bore size must match your cutting machine's specifications. Using an incorrect arbor size is a safety hazard and will cause poor performance.

Tooth count is crucial. A higher tooth count yields a finer finish but cuts slower. A lower tooth count cuts faster but with a rougher edge. For general-purpose pipe cutting, a medium tooth count often provides the best balance.

Finally, consider special coatings like titanium nitride (TiN). Coated high speed steel cutting blade options last longer, run cooler, and reduce friction. For high-volume production, the investment in a premium coated blade from a trusted supplier like SANSO can significantly reduce downtime and cost per cut.

Proper care extends the service life of any tool. A high speed steel cutting blade is no exception.

Always use the correct cutting speed (RPM) and feed rate. Pushing the blade too hard generates excessive heat, the main enemy of tool life. Let the blade cut at its designed pace.

Use adequate coolant or lubricant whenever possible. This reduces heat, clears chips from the gullets, and improves both cut quality and blade longevity. For dry cutting applications, ensure you have chosen a blade grade specifically designed for that purpose.

Avoid lateral pressure or twisting the blade during a cut. Ensure the pipe is clamped securely to prevent vibration and chatter, which can damage teeth.

Regularly inspect the blade for signs of wear, such as dull teeth, chipping, or discoloration from overheating. A sharp blade is a safe and efficient blade. Dull blades require more force, generate more heat, and produce poor-quality cuts.

Implementing a routine sharpening schedule with a professional service is more economical than running blades until they are completely destroyed. A brand like SANSO can often provide or recommend reliable sharpening services for their products.

Within the tube mill environment, the high speed steel cutting blade performs a specific, vital role. After pipe is formed and welded, it travels in a continuous length to the cut-off station.

Here, a high-speed saw, often synchronized with the line speed, moves with the pipe and makes a clean, burr-minimized cut to the desired length. The blade must engage and disengage quickly and cleanly.

The choice of HSS for this application is driven by its ability to perform this intermittent cutting cycle repeatedly while maintaining an edge. It handles the varying wall thicknesses and material grades common in production runs. For mills processing a mix of materials or with moderate output speeds, a well-chosen high speed steel cutting blade offers an excellent balance of performance and operational cost.

While carbide-tipped blades may be used for ultra-high-volume or abrasive materials, the HSS blade remains a cost-effective and highly capable solution for a vast range of pipe milling applications.

Not all HSS blades are created equal. The quality of the base steel, the precision of the tooth grinding, and the consistency of heat treatment separate premium blades from inferior ones.

A poorly made blade will lose its edge quickly, vibrate excessively, and can even fail catastrophically. This leads to unsafe conditions, production stoppages, and damaged material.

This is why partnering with a reputable manufacturer is critical. Brands like SANSO have built their reputation in the metalworking industry by providing consistently high-quality cutting tools. Their high speed steel cutting blade products are engineered for specific industrial applications, ensuring reliable performance in the tough environment of a pipe mill. Investing in a trusted brand translates to predictable results, fewer changeovers, and lower total cost over time.

For international welding pipe milling, where equipment must perform day in and day out, the reliability of every component is paramount. Your cutting blades are no exception.

Q1: Can a high-speed steel cutting blade cut stainless steel pipe?

A1: Yes, but with important caveats. Special HSS grades (like M42 or M51 with higher cobalt content) are better suited for stainless steel's work-hardening properties. Cutting speed must be significantly reduced, and ample coolant is absolutely essential. For frequent stainless steel cutting, consulting with a specialist like SANSO for the correct blade specification is highly recommended.

Q2: How often should I replace or sharpen my HSS cutting blade?

A2: There's no fixed timeline; it depends on usage, material, and operating conditions. Monitor cut quality and cutting pressure. Increased burr, slower feed rates, excessive sparking, or a burnt finish on the pipe are clear signs the blade needs attention. Proactive sharpening after a set number of operating hours is better than waiting for complete failure.

Q3: What is the main difference between an HSS blade and a Carbide-Tipped blade?

A3: The cutting teeth material. HSS blades have teeth made entirely of high-speed steel. Carbide-tipped blades have small, brazed tips of tungsten carbide, an extremely hard, wear-resistant material. Carbide blades can run at higher speeds and last much longer on abrasive materials but are more brittle and expensive. HSS blades are tougher, more resistant to shock, and generally more cost-effective for general-purpose pipe cutting.

Q4: Why is coolant so important when using a high-speed steel cutting blade?

A4: Coolant serves three main functions: it reduces heat at the cutting edge to preserve the blade's hardness, it lubricates to reduce friction and power consumption, and it flushes away metal chips to prevent them from being re-cut and damaging the blade or workpiece. Proper coolant use can easily double or triple the life of an HSS blade.

Q5: My blade is vibrating and making a loud noise during the cut. What's wrong?

A5: This is often a sign of a problem. Possible causes include a dull or damaged blade, incorrect blade mounting (not tightened properly on the arbor), worn machine bearings or arbors, or an incorrect blade type for the material/thickness. Stop the machine immediately, inspect the high speed steel cutting blade for damage, and check all machine components. Continued use can be dangerous and will ruin both the blade and the workpiece.