Choosing the right cutting tool is critical for efficiency and precision in metalworking and fabrication. For professionals in international welded pipe and tube milling, as well as general manufacturing, the circular saw blade HSS represents a core component of their cutting arsenal. High-Speed Steel blades offer a unique balance of toughness and cutting ability for various ferrous and non-ferrous metals. Brands like SANSO have developed specific circular saw blade HSS options engineered to meet the rigorous demands of continuous production, where clean cuts and minimal downtime are essential. This article will guide you through the essential aspects of these blades.

High-Speed Steel is a specialized tool steel that maintains its hardness even at high temperatures generated during cutting. This "red-hardness" is what sets it apart from simpler carbon steel blades.

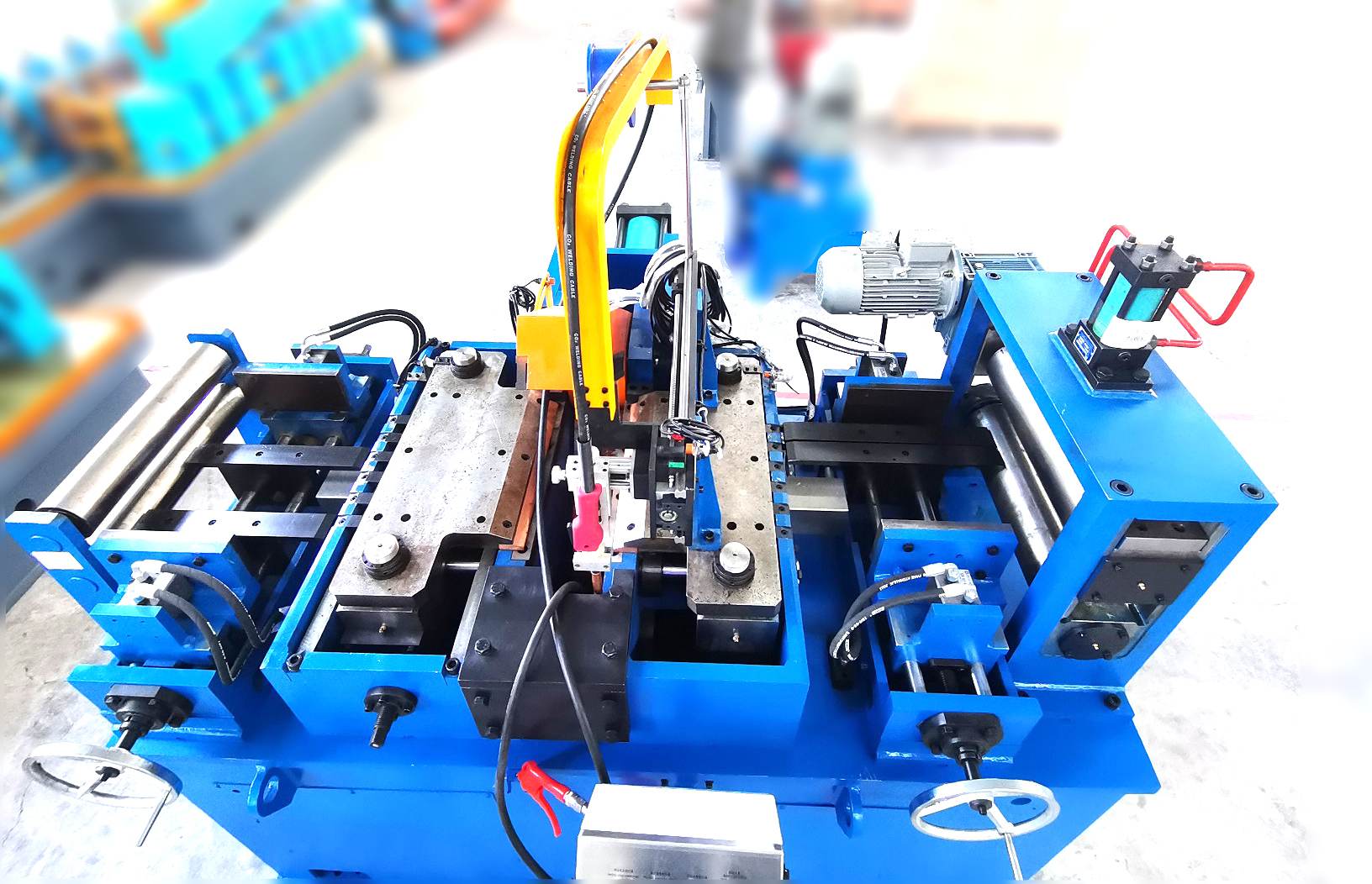

A circular saw blade HSS is not made from a single piece of HSS. Instead, the teeth are often tipped or fully made from this durable material. The core of the blade is typically a strong, flexible alloy steel body that can withstand the torsional forces of cutting. The HSS teeth are then welded or bonded to this core.

These blades are particularly effective for cutting solid sections, pipes, and profiles. In welded tube mills, they are often used for sample testing and offline cutting operations. They handle materials like:

To make an informed choice, you need to understand the physical characteristics that dictate a blade's performance.

The shape and arrangement of the teeth determine cut quality, speed, and material suitability.

Always review these numbers on the blade or its packaging:

While carbide-tipped blades are excellent for extreme hardness, circular saw blade HSS options have distinct advantages.

Don't just grab any blade. Match it to your specific task to ensure safety, quality, and tool longevity.

This is the most important step. Using a blade designed for aluminum on stainless steel will lead to poor results and rapid dulling.

The saw itself dictates limits.

A circular saw blade HSS is a significant investment. Proper care ensures it pays for itself many times over.

Regular maintenance is non-negotiable.

Selecting the optimal circular saw blade HSS requires careful consideration of material, machine, and desired outcome. It is a decision that directly impacts project timelines, finish quality, and operational costs in demanding fields like welded tube manufacturing. By understanding the advantages of High-Speed Steel, the importance of tooth geometry, and the non-negotiable need for proper maintenance, you can achieve cleaner cuts and greater productivity. For those seeking a reliable blend of durability and performance, exploring the range offered by established brands like SANSO provides a solid starting point for finding a blade that meets professional standards.

Q1: How long does a typical circular saw blade HSS last before it needs sharpening?

A1: There's no fixed hour count. It depends entirely on the materials cut, feed rate, and power of your saw. A blade cutting soft aluminum may last for hours of continuous use, while cutting abrasive stainless steel will dull it faster. The key is to watch for signs: increased cutting force, burning smells, and a noticeably rougher cut finish all indicate it's time for sharpening.

Q2: Can I use one HSS blade to cut both steel and aluminum?

A2: It is not recommended. Blades for aluminum have specific geometry and surface treatments to prevent "loading," where soft metal gums up the teeth. Using an aluminum blade on steel will likely overheat and dull it quickly. Using a steel blade on aluminum can cause dangerous grabbing and a poor finish. Dedicated blades are safer and more cost-effective.

Q3: What is the main difference between an HSS blade and a carbide-tipped blade?

A3: The material on the cutting teeth. HSS (High-Speed Steel) teeth are made from a tough, heat-resistant alloy steel that can be sharpened easily. Carbide teeth are made from a sintered tungsten carbide compound that is much harder and more wear-resistant but also more brittle. Carbide stays sharper longer on abrasive materials but is more expensive and susceptible to chipping from impact.

Q4: My HSS blade is smoking and burning the material. What am I doing wrong?

A4: Burning and smoking are almost always caused by excessive heat. This can result from several factors: a dull blade that needs sharpening, too high a feed rate (pushing too fast), too low a saw speed (RPM), or a lack of appropriate cutting fluid for the material. Stop and check these variables before continuing.

Q5: Is it worth re-sharpening a circular saw blade HSS, or should I just buy a new one?

A5: For a quality blade from a reputable manufacturer, sharpening is almost always worth it. A professional sharpening service can restore the blade to like-new performance at a fraction of the cost of a replacement. This can be done multiple times over the blade's life, making it a very economical choice. Only discard a blade if the steel body is damaged or the teeth are extensively chipped beyond repair.