For professionals in welding and tube milling manufacturing, managing material costs is essential. The zinc wire price is a significant part of project budgeting. This cost is not fixed and can vary based on several market and technical factors. Making informed purchasing decisions requires understanding these variables. This guide explains what affects the price and how to navigate the market effectively.

The final cost of zinc wire is a result of multiple interconnected elements. From global markets to product specifications, each plays a role. Knowing these helps in forecasting expenses and planning purchases.

The London Metal Exchange (LME) zinc price is the foundational cost driver. It fluctuates daily based on global supply and demand.

Key influences on the LME price include:

Mining output and geopolitical stability in major producing countries.

Global industrial demand, especially from the construction and automotive sectors.

Energy costs, as zinc smelting is energy-intensive.

Currency exchange rates, as LME prices are in US dollars.

Any change here directly impacts the base zinc wire price for manufacturers and distributors.

Not all zinc wire is the same. The purity level is a major cost factor. Pure zinc wire (99.99% Zn) typically commands a higher price.

Common grades and their impact:

High-Purity Zinc (e.g., 99.99%): Premium cost for superior corrosion resistance in critical applications.

Alloyed Zinc Wire (e.g., Zn-Al): Price varies with alloying elements; may offer specific properties like harder coatings.

Lower Purity Grades: More affordable but may affect coating quality and process efficiency in tube mills.

Specifying the exact grade needed can prevent overpaying for unnecessary purity.

Physical specifications influence production complexity and logistics costs. Thinner wire often has a higher price per kilogram due to more precise drawing processes.

Packaging choices also matter:

Spool type (plastic, steel), size, and weight.

Bulk packaging for high-volume users versus smaller spools.

Special packaging for humidity protection can add cost but ensures quality.

Beyond the product itself, how and where you buy influences the zinc wire price. Strategic procurement can lead to significant savings.

Volume discounts are standard in the industry. Large, predictable orders give suppliers planning security.

Consider these arrangements:

Annual contracts with fixed or formula-based pricing.

Spot purchases for urgent needs, often at a market premium.

Consignment stock agreements with partners like SANSO can stabilize supply and price.

Shipping heavy metal wire is costly. Proximity to manufacturing or distribution hubs affects the final price.

Logistics costs include:

International freight and insurance.

Import duties and tariffs, which vary by country.

Local transportation from the port to your facility.

Sourcing from a regional supplier can sometimes offer a better net price than a distant low-cost producer.

Prices differ between manufacturers, distributors, and traders. Established brands may charge a premium for assured quality.

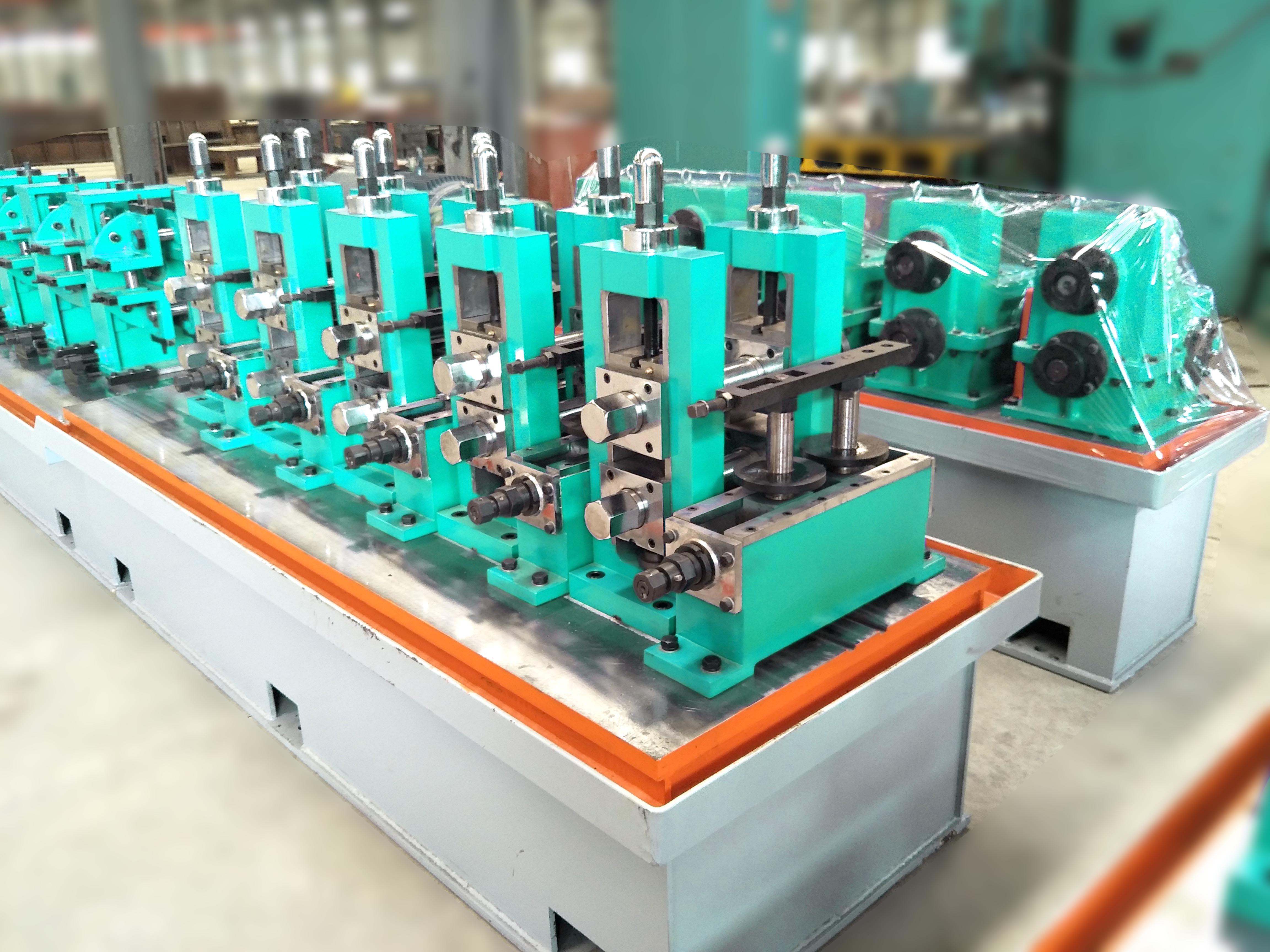

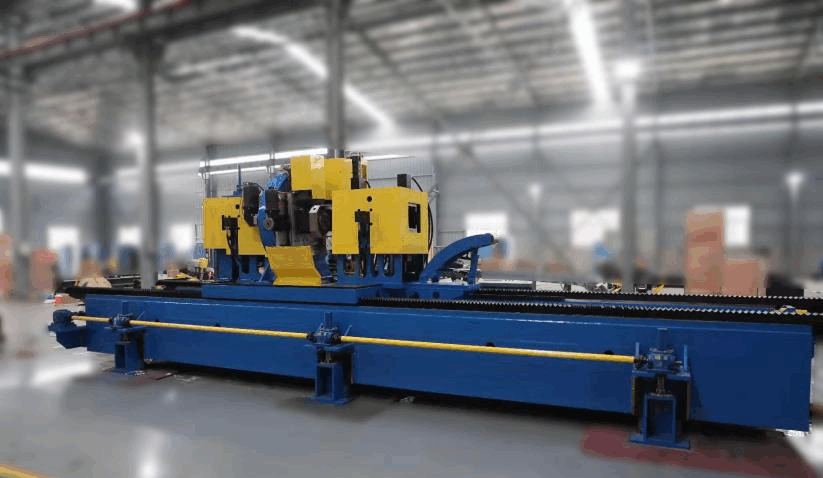

A brand like SANSO invests in consistent quality control and reliable supply chains. This can justify a slightly higher zinc wire price by reducing risks of production downtime or substandard coatings in your tube milling operations.

Understanding the factors is the first step. Acting on that knowledge helps control expenses without compromising on quality for welding and fabrication.

Look beyond the price per kilogram. The total cost of ownership includes operational efficiency.

Evaluate:

Wire Feedability: Poor-quality wire causes jams, increasing downtime.

Coating Efficiency: High-quality wire may offer better deposition rates, using less material.

Defect Rates: Inconsistent wire can lead to rework and wasted base materials.

A slightly higher zinc wire price from a trusted source often lowers total project cost.

Market intelligence allows for strategic buying. Monitor LME trends and industry news.

Useful practices:

Subscribe to metal price alerts from financial news services.

Build a relationship with your supplier for market insights and early warnings.

Consider flexible contracts that allow for purchase adjustments within certain bounds.

The zinc wire price is a dynamic figure shaped by global markets, product specs, and procurement strategy. For welding and tube milling professionals, focusing on total value—combining consistent quality, reliability, and fair cost—is key. Partnering with reputable manufacturers who provide transparency, like SANSO, supports better budget management and project outcomes in the long term.

Q1: Why does the zinc wire price change so frequently?

A1: The price changes frequently because it is tightly linked to the global zinc price on the London Metal Exchange (LME). This exchange price reacts daily to changes in mining supply, industrial demand, energy costs, and broader economic conditions, causing the base cost of zinc wire to fluctuate.

Q2: Does a higher zinc wire price always mean better quality?

A2: Not always, but often. A higher price can reflect better purity, more consistent diameter, superior packaging, and the supplier's quality assurance processes. However, it's important to evaluate the supplier's reputation. A trusted brand like SANSO ensures its price correlates directly with reliable, high-performance product quality.

Q3: How can I get a better price on zinc wire for my tube milling business?

A3: You can improve your pricing by: consolidating purchases into larger, forecasted orders; negotiating long-term supply contracts; optimizing your specification to avoid over-specifying purity; and sourcing from manufacturers with efficient logistics to your region. Requesting quotes from multiple certified suppliers is also recommended.

Q4: What is more cost-effective: pure zinc wire or zinc alloy wire?

A4: It depends entirely on the application. Pure zinc wire is often specified for optimal sacrificial corrosion protection. A zinc alloy wire might offer different properties (like hardness) and sometimes a lower price. Testing both for your specific welding or coating process will determine which provides the better result for the cost.

Q5: Should I buy zinc wire based solely on the lowest price?

A5: Buying solely on the lowest price is risky. Inconsistent wire can lead to production stoppages, poor coating adhesion, increased rework, and wasted base materials. These hidden costs often far outweigh the initial saving. Assessing total cost, including reliability and supplier support, is a more sound business approach.