In the international welding and tube milling manufacturing sector, materials that offer reliability and performance are key. Pure zinc wire stands out for its role in corrosion protection and structural integrity. This article delves into its diverse applications, helping professionals make informed choices. Brands like SANSO provide high-quality options that meet industry standards.

Pure zinc wire is a metallic product made from high-purity zinc, typically above 99.9% zinc content. It is widely used in industrial processes for coating and joining metals. In welding and tube fabrication, it ensures long-lasting protection against environmental damage.

The composition of pure zinc wire focuses on minimal impurities. This enhances its effectiveness in applications. Key properties include:

High corrosion resistance due to zinc's sacrificial anode behavior.

Good electrical conductivity for welding processes.

Ductility, allowing easy handling in tube milling machines.

Melting point around 419°C, suitable for various manufacturing setups.

These traits make pure zinc wire a staple in many fabrication workflows. Its purity levels, as seen in products from SANSO, ensure consistent results.

Purity in zinc wire directly impacts performance. Impurities can lead to weak coatings or welding defects. In tube milling, high-purity zinc wire provides uniform coatings that resist rust. This reduces maintenance costs and extends product lifespan. For instance, SANSO's pure zinc wire maintains strict purity controls for reliable outcomes.

Pure zinc wire is integral to modern welding techniques. It helps create durable joints and protective layers on metal surfaces. From automotive to construction, its applications are vast.

Galvanizing involves coating steel or iron with zinc to prevent rust. Pure zinc wire is often used in hot-dip galvanizing processes. It melts and forms a barrier against moisture and chemicals. Benefits include:

Extended service life for welded structures.

Cost savings by reducing replacement needs.

Enhanced safety in corrosive environments like marine settings.

In pipeline welding, pure zinc wire ensures seams remain protected. This is crucial for international projects where durability is paramount.

Welding methods like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) utilize pure zinc wire as a filler material. It bonds well with base metals, providing strength. Applications include:

Repairing galvanized surfaces without losing corrosion resistance.

Joining tubes in HVAC systems where moisture exposure is high.

Fabricating industrial equipment that requires zinc-rich coatings.

Using high-quality pure zinc wire, such as from SANSO, minimizes weld spatter and improves finish quality. This boosts efficiency in production lines.

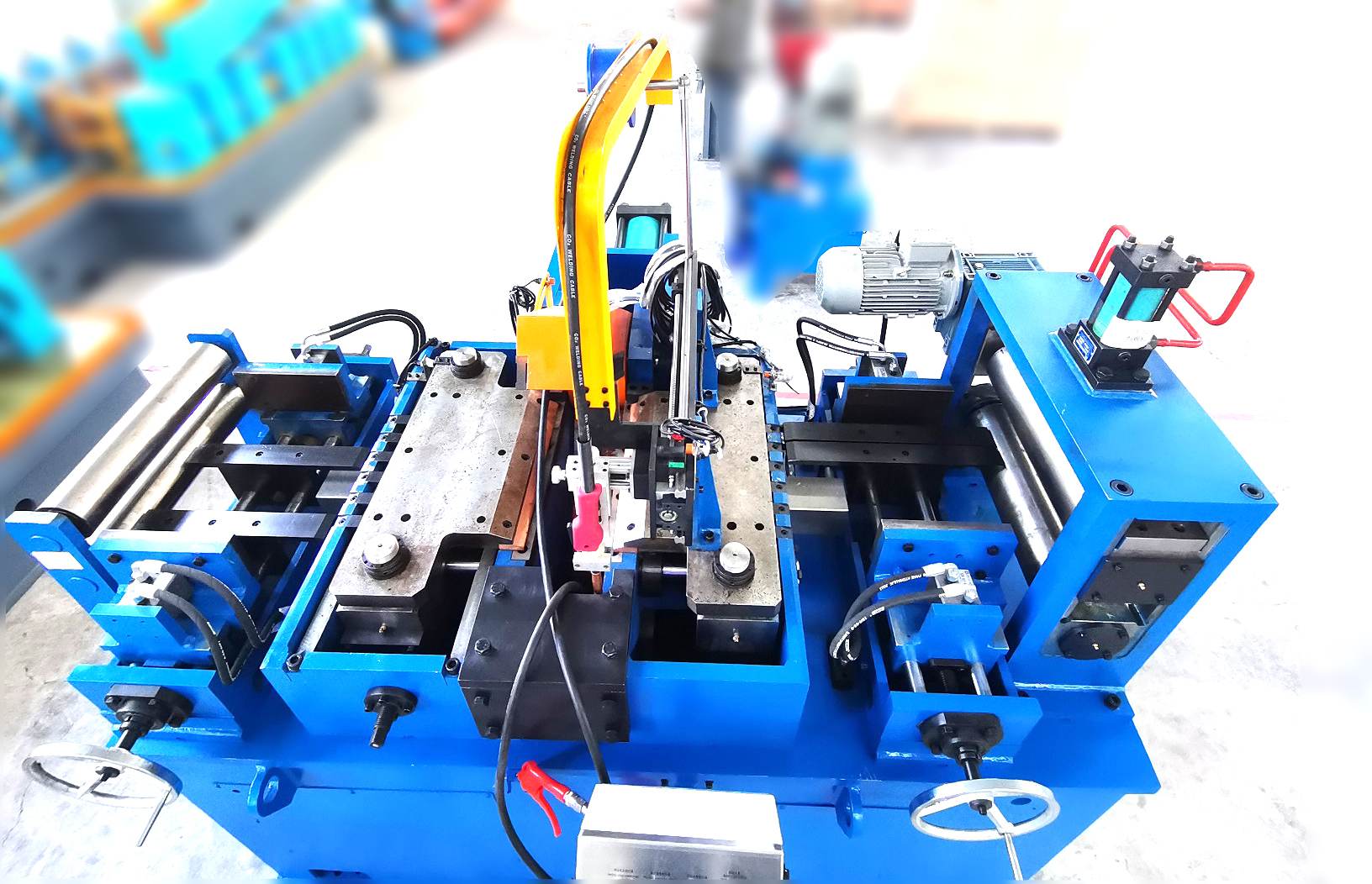

Tube milling involves shaping and processing metal tubes for various industries. Pure zinc wire plays a key role in coating and finishing stages. It helps produce tubes that resist wear and tear.

During tube milling, pure zinc wire is applied via spraying or electroplating. This creates a uniform zinc layer on tube surfaces. Advantages include:

Improved aesthetic appeal with a shiny, protective finish.

Better adhesion for subsequent paint or powder coatings.

Reduced friction in mechanical systems, enhancing flow efficiency.

In automotive exhaust systems, pure zinc wire coatings prevent rust from high temperatures. Manufacturers rely on consistent supplies, like those from SANSO, to meet tight deadlines.

The durability of tubes is critical in construction and machinery. Pure zinc wire adds a protective barrier that withstands harsh conditions. Key benefits are:

Long-term corrosion resistance, even in acidic or alkaline environments.

Minimal maintenance needs, lowering operational costs.

Compliance with international standards for safety and quality.

For tube milling operations, investing in pure zinc wire ensures products last longer. Brands like SANSO offer grades tailored to specific manufacturing demands.

Selecting appropriate pure zinc wire involves considering factors like diameter, purity, and application. Making the right choice enhances project outcomes and reduces waste.

When sourcing pure zinc wire, evaluate these aspects:

Diameter and spool size: Match to welding or coating equipment specifications.

Purity level: Opt for higher purity (e.g., 99.99%) for critical applications.

Packaging: Ensure it prevents contamination during storage and transport.

Supplier reputation: Choose reliable brands with proven track records.

In tube milling, thicker pure zinc wire might be used for heavy-duty coatings. Testing samples can help verify compatibility with existing processes.

SANSO is known for producing pure zinc wire that meets rigorous international standards. Their products feature:

Consistent purity levels, verified through third-party testing.

Customizable options for specific welding or milling needs.

Eco-friendly manufacturing processes that reduce environmental impact.

By incorporating SANSO's pure zinc wire, companies can achieve reliable performance. This supports efficient production in welding and tube fabrication sectors.

Pure zinc wire is a versatile material essential for welding and tube milling manufacturing. Its applications range from corrosion protection to enhancing product durability. As industries globalize, using high-quality options like those from SANSO can drive success. Embracing this material leads to stronger, longer-lasting outcomes in various projects.

Q1: What is pure zinc wire commonly used for in welding?

A1: Pure zinc wire is commonly used in welding for galvanizing and as a filler material. It provides corrosion resistance to welded joints, especially in environments exposed to moisture or chemicals. In processes like MIG welding, it helps create durable seams on steel structures.

Q2: How does pure zinc wire benefit tube milling operations?

A2: In tube milling, pure zinc wire benefits operations by applying protective coatings to tube surfaces. This prevents rust and wear, extending the lifespan of tubes used in construction, automotive, and industrial systems. It ensures smooth finishes and reduces maintenance costs.

Q3: What purity level should I look for in pure zinc wire?

A3: For most industrial applications, look for pure zinc wire with a purity level of at least 99.9%. Higher purity, such as 99.99%, is recommended for critical tasks where impurities could cause defects. Brands like SANSO offer options with certified purity levels.

Q4: Can pure zinc wire be used in high-temperature environments?

A4: Yes, pure zinc wire can be used in high-temperature environments, but its effectiveness depends on the coating method. In hot-dip galvanizing, it forms a stable layer that withstands temperatures up to 200-300°C. For extreme heat, consult specifications to ensure compatibility.

Q5: How do I store pure zinc wire to maintain its quality?

A5: Store pure zinc wire in a dry, cool place away from moisture and direct sunlight. Use original packaging or sealed containers to prevent oxidation and contamination. Regularly inspect for damage, and follow supplier guidelines, such as those from SANSO, for optimal shelf life.