In the demanding fields of welding and tube milling, precision and durability are non-negotiable. The right cutting tool can mean the difference between a perfect seam and costly rework. A TCT cutting blade stands out as a critical component for professionals. These blades are engineered for cutting through various metals efficiently. Brands like SANSO have refined this technology to meet high industrial standards. This guide explores essential aspects of selecting and using a TCT cutting blade in metal fabrication.

What is a TCT Cutting Blade?

A TCT cutting blade is a circular saw blade with teeth made from tungsten carbide. These tips are brazed onto a high-strength steel body. This combination offers exceptional hardness and heat resistance.

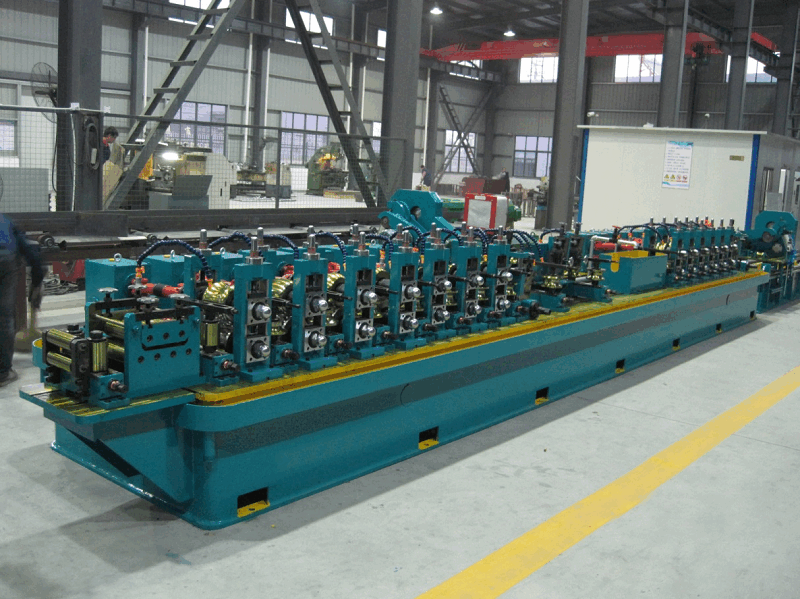

In international tube milling operations, such blades are vital. They prepare pipe ends for welding with high accuracy. Their performance directly impacts the quality of the final welded structure.

Core Components and Construction

The effectiveness of a TCT blade comes from its build. Understanding its parts helps in making a better choice.

Tungsten Carbide Tips: Extremely hard material that retains sharpness longer than steel.

Steel Core: Provides the blade's structure, flexibility, and ability to withstand cutting forces.

Tooth Geometry: The shape of the teeth affects cutting speed, finish, and material type.

Primary Advantages in Metal Fabrication

Why has the TCT cutting blade become a standard? Its benefits are clear in day-to-day industrial use, especially in welding preparation.

Superior Longevity and Cost Efficiency

Carbide tips are much more wear-resistant than high-speed steel. A single TCT cutting blade can outlast dozens of conventional blades.

Reduces frequency of blade changes.

Lowers long-term tooling costs despite a higher initial price.

Minimizes machine downtime for higher productivity.

Enhanced Cut Quality and Precision

For tube milling, a clean, square cut is essential for proper weld alignment. TCT blades deliver this consistency.

They produce smooth edges with minimal burr. This reduces or eliminates secondary finishing work before welding.

How to Select the Right TCT Cutting Blade

Choosing the correct TCT cutting blade requires attention to several specifications. The wrong blade can lead to poor results and potential safety issues.

1. Material to be Cut

Different metals require different blade designs. This is the first and most important factor.

Aluminum & Non-Ferrous: Use a blade with a high tooth count and a positive hook angle for smooth cuts.

Steel & Ferrous Metals: Opt for a lower tooth count and a neutral or negative hook angle to control heat and tooth engagement.

Stainless Steel: Requires a specialized grade of carbide and specific geometry to work-hardening properties.

2. Tooth Design and Count

Tooth design dictates the cutting action.

Alternate Top Bevel (ATB): Common for cross-cutting and fine finishes.

Triple Chip Grind (TCG): Ideal for hard metals, alloys, and materials prone to chipping.

More teeth give a finer finish but cut slower. Fewer teeth remove material faster but leave a rougher edge.

3. Blade Diameter and Arbor Size

These must match your cutting machine's specifications. Using an incorrectly sized blade is dangerous and inefficient.

4. RPM Rating and Application Speed

Never exceed the maximum RPM marked on the blade. Match the blade's speed rating to your machine's operating speed.

5. Brand and Quality Assurance

Invest in blades from reputable manufacturers. For instance, SANSO's TCT cutting blade range is known for consistent quality and reliable performance in industrial settings.

Their blades undergo rigorous testing to ensure they meet the demands of continuous tube milling and welding preparation.

Applications in Welding and Tube Milling

The TCT cutting blade is indispensable in specific fabrication stages. Its role is critical for ensuring weld integrity.

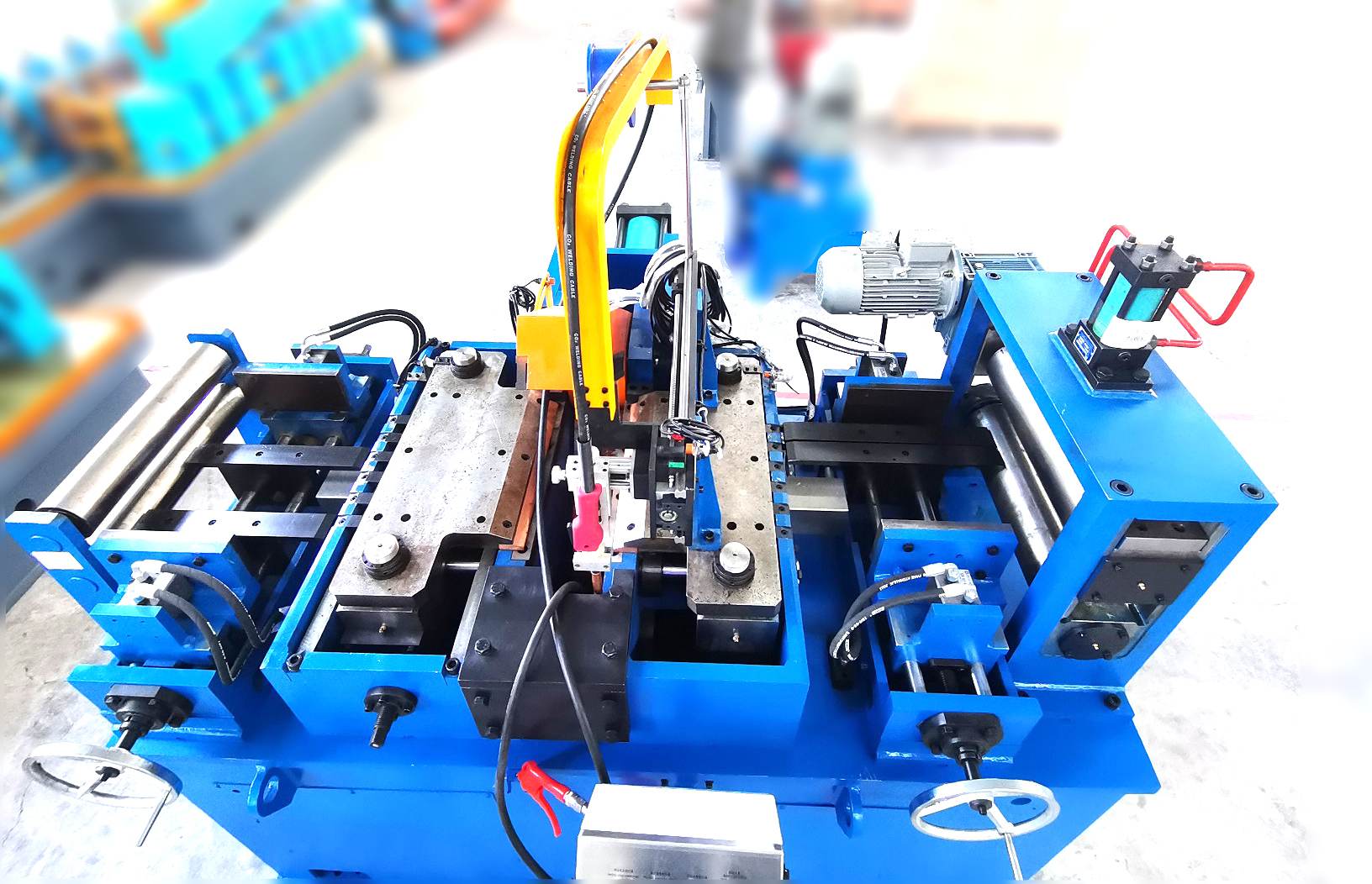

Pipe End Preparation for Welding

Before welding, pipe ends must be cut squarely and cleanly. Tube milling machines use TCT blades to achieve this.

A precise cut ensures proper fit-up, leading to stronger, more reliable welds with less internal stress.

Notching and Deburring Operations

Beyond straight cuts, these blades are used for creating complex joints and removing sharp edges from cut pieces.

Maintenance and Safety Best Practices

Proper care extends the life of your TCT cutting blade and ensures operator safety.

Routine Cleaning and Inspection

Resin and metal chips can build up on the blade, reducing efficiency.

Clean blades regularly with an appropriate solvent.

Inspect for missing, chipped, or dull teeth.

Check for cracks in the steel body or around the brazing points.

Correct Storage and Handling

Store blades in their original packaging or on a rack in a dry place. Avoid dropping them, as carbide tips can chip.

Prioritizing Safety

Always wear appropriate PPE: safety glasses, gloves, and hearing protection. Ensure the workpiece is securely clamped.

Let the blade reach full speed before contacting the material, and never force the cut.

Why SANSO is a Trusted Name for Professionals

In a market with many options, SANSO has built a reputation for reliability. Their focus on the industrial sector means their TCT cutting blade products are designed for real-world challenges.

They use high-grade carbide and precise manufacturing processes. This results in blades that offer consistent performance, crucial for meeting production targets in welding and tube milling.

Choosing a trusted brand like SANSO can provide peace of mind and predictable results on the shop floor.

Selecting the optimal TCT cutting blade is a technical decision with significant impact on fabrication quality and cost. By considering the material, tooth design, and operational specs, you can achieve cleaner cuts and higher productivity.

Regular maintenance and adherence to safety protocols will maximize your investment. For professionals in welding and tube milling, leveraging quality tools from manufacturers like SANSO is a step toward more efficient and reliable metal fabrication.

Frequently Asked Questions (FAQ)

Q1: How long does a typical TCT cutting blade last compared to a standard steel blade?

A1: A TCT cutting blade lasts significantly longer. It can last 10 to 50 times longer than a high-speed steel blade when cutting metal, depending on the material and usage conditions. This makes it far more cost-effective over time.

Q2: Can I use one TCT cutting blade for all metals?

A2: No, it is not recommended. While versatile, optimal performance requires matching the blade to the metal. Using an aluminum-cutting blade on steel, for example, can lead to rapid dulling, poor cuts, and potential safety hazards.

Q3: What's the most important sign that my TCT blade needs replacing?

A3: The key signs are a noticeable increase in cutting force or resistance, excessive sparking, a rough or burnt finish on the cut edge, and visible chipping or wear on the carbide tips. Reduced cutting speed is another indicator.

Q4: Is it safe to sharpen a TCT cutting blade myself?

A4: Sharpening a TCT blade requires specialized diamond grinding equipment and expert knowledge of tooth geometry. It is not a DIY task. For consistent and safe results, send dull blades to a professional sharpening service.

Q5: Why might a fabricator choose a SANSO TCT blade over other brands?

A5: Fabricators might choose SANSO for their documented consistency, use of premium carbide grades, and design focused on industrial applications like tube milling. Their blades are engineered to provide reliable performance, reducing variability in high-precision fabrication work.