In welded tube and pipe manufacturing, material preparation is a critical first step. A coil slitting line is essential for processing master coils into narrower strips. These strips are then fed into tube forming mills.

The right slitting line improves material yield and product quality. It directly impacts the efficiency of the entire production process. For manufacturers, selecting the correct system requires careful evaluation.

This guide outlines seven important factors to consider. It is designed for professionals in international tube and pipe manufacturing. Brands like SANSO provide advanced solutions in this field.

A coil slitting line processes wide steel coils. It cuts them into multiple narrower strips of precise width. This process is known as slitting.

These slit coils become the feedstock for tube mills. Consistent strip width is vital for high-quality welded tube production. It ensures proper forming and a stable welding process.

The main tasks of a slitting line include:

Unwinding the master coil smoothly and under control.

Flattening and leveling the material for accurate cutting.

Slitting the coil into predetermined widths using rotary knives.

Rewinding the slit strands into tight, manageable coils.

This prepared material feeds directly into tube forming and welding equipment. A reliable coil slitting line is a cornerstone of an efficient tube mill.

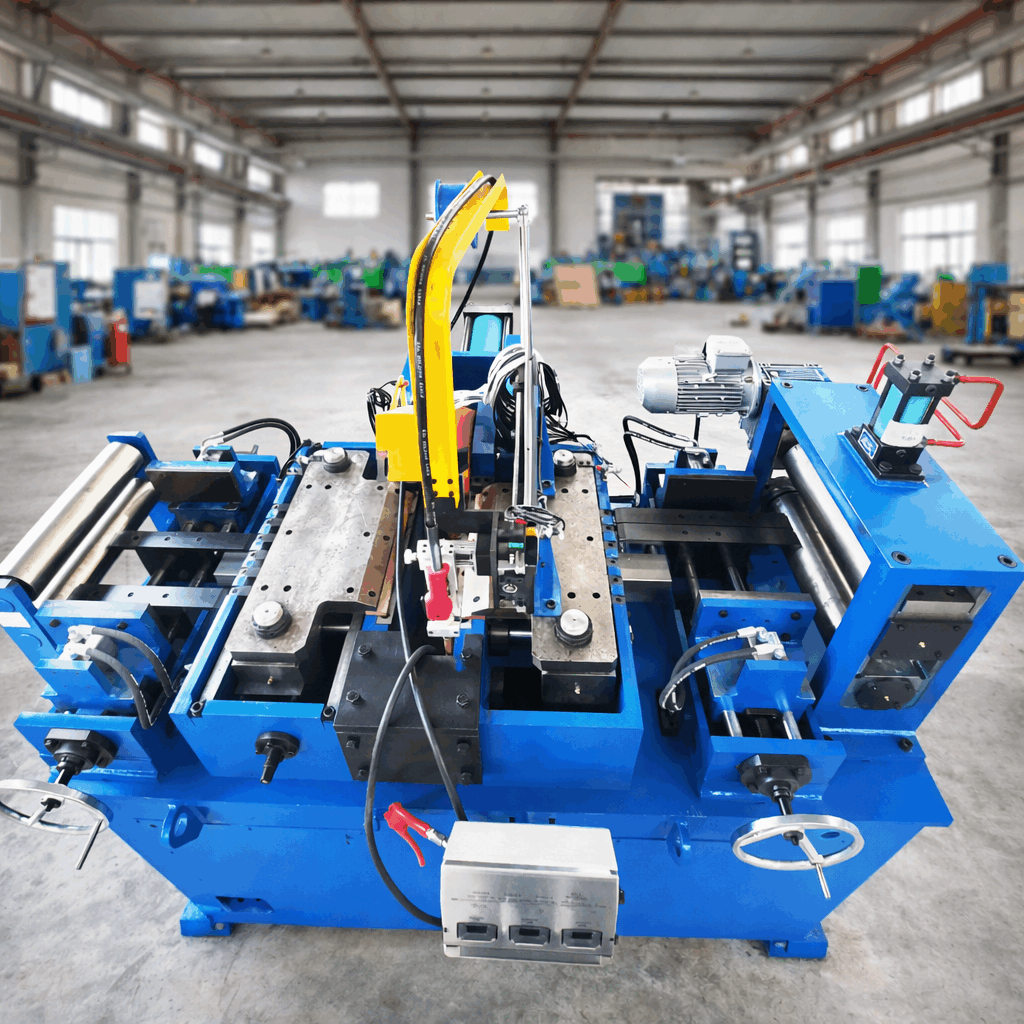

A typical system consists of several integrated machines. Each component has a specific function. Understanding them helps in specifying the right line.

The main components work in a sequential process. They handle the material from loading to final unloading.

Pay-off Reel (Uncoiler): Holds and unwinds the master coil. It must provide controlled tension.

Entry Pinch Roll & Leveler: Feeds the strip and removes coil set or crossbow.

Slitter Head: The heart of the line. Contains the top and bottom rotary knives that perform the cutting.

Separator System: Keeps slit strands from tangling after the cutter head.

Tension Stand: Maintains proper strip tension before rewinding.

Recoiler: Winds the individual slit strands into new, tight coils.

Additional components like scrap winders and edge trimmers are also common. The build quality of each part determines the line's reliability.

Your material defines the machine you need. Not all slitting lines handle the same range of steel.

You must match the line's technical specs with your production materials. This avoids premature wear and ensures clean slits.

Consider these material properties when selecting equipment:

Material Grade: Mild steel, high-strength steel, stainless steel, or coated metals (galvanized, aluminized).

Thickness Range: The minimum and maximum gauge the line can process cleanly (e.g., 0.5mm to 4.0mm).

Coil Width: The maximum input width of the master coil.

Coil Weight: The maximum weight and inner/outer diameter the uncoiler and recoiler can handle.

Yield Strength: Higher strength materials require more powerful equipment.

Manufacturers like SANSO design lines for specific material ranges. Providing accurate data ensures you get a suitable coil slitting line.

The quality of the slit edge is paramount. A poor edge can cause problems in the tube mill.

Burrs, camber, or edge strain affect forming and welding. High-precision slitting prevents these issues.

Several factors influence the final strip quality:

Knife Design and Material: Tool steel quality, hardness, and blade angle.

Knife Setup and Clearance: Precise horizontal and vertical alignment is critical.

Machine Rigidity: The slitter head and frame must not flex under load.

Strip Guidance: Proper entry and exit guides keep the material aligned.

Modern lines use CNC setups for knife positioning. This ensures repeatable accuracy and reduces setup time between jobs.

Line speed impacts overall throughput. However, speed must be balanced with accuracy and material type.

A faster line is not always better if it compromises edge quality or requires constant adjustment.

Look beyond the maximum meter-per-minute rating. Consider these efficiency factors:

Setup Time: How quickly can knife changes and width adjustments be made?

Automation Level: Automated coil loading, threading, and tail-out can reduce labor and downtime.

Line Control System: User-friendly interfaces and recipe storage for common jobs.

Scrap Handling: Integrated scrap winding systems keep the line clean and safe.

An efficient coil slitting line maximizes productive running time. It minimizes the downtime between processing different coils.

The slitting line is not a standalone island. It must feed seamlessly into your tube forming and welding equipment.

Integration considers both physical layout and production flow. Planning this connection is crucial for a smooth operation.

Material Flow: Logical placement between coil storage and the tube mill entry.

Strip Width and Tolerance: The slit strip must match the input requirements of your tube mill.

Coil Handling: How will finished slit coils be transported to the tube mill's decoiler?

Control Compatibility: Potential for data exchange or production scheduling links.

Suppliers with broad experience in complete tube mills, such as SANSO, can advise on optimal integration. Their expertise ensures the coil slitting line complements your other equipment.

Industrial equipment must prioritize operator safety. Good design protects personnel and reduces liability.

Similarly, easy maintenance design ensures long-term reliability and lower operating costs.

When evaluating a slitting line, check for these features:

Safety Guards: Full enclosure of moving parts, especially the slitter head.

Emergency Stops: Clearly placed and accessible emergency stop buttons along the line.

Lockout/Tagout Points: Provisions for safe maintenance procedures.

Accessibility: Easy access to knives, bearings, and motors for routine service.

Lubrication Systems: Centralized or easily accessible grease points.

A well-built line is designed for safe operation and straightforward upkeep. This contributes to higher overall equipment effectiveness.

Selecting the right coil slitting line is a significant investment. It requires balancing technical capabilities, material needs, and budget.

The seven factors outlined provide a structured approach to this decision. They help you evaluate options from different suppliers effectively.

For manufacturers seeking reliable performance, exploring solutions from established brands is wise. SANSO offers engineering and equipment designed for the demands of tube production. A well-chosen line becomes a reliable and productive part of your manufacturing process for years to come.

Q1: What is the main purpose of a coil slitting line in a tube mill?

A1: The main purpose is to process wide master steel coils into multiple narrower strips. These strips have precise widths and good edge quality, making them suitable as feedstock for tube forming and welding mills.

Q2: How does the slitting process actually work?

A2: The process uses a set of matched rotary knives. The steel strip passes between a top and bottom knife set for each desired slit. It is a shearing action that produces clean edges, unlike burning or sawing.

Q3: What is the difference between slitting and shearing?

A3: Slitting uses rotary knives to make longitudinal cuts along a moving coil, producing multiple strips. Shearing typically uses a straight blade to cut across the width of a stationary sheet or coil, producing shorter lengths or blanks.

Q4: How important is knife maintenance for a slitting line?

A4: It is critically important. Sharp, properly aligned knives are essential for producing burr-free edges, maintaining dimensional accuracy, and minimizing tooling force. Dull or misaligned knives produce poor quality strips and can damage the machine.

Q5: Can a single slitting line handle very different materials, like thin galvanized steel and thick mild steel?

A5: Usually not optimally. While some lines have a broad range, most are designed for a specific thickness and material strength bracket. Processing material outside the design range leads to poor quality, rapid knife wear, or machine strain. It's best to specify your primary material range.