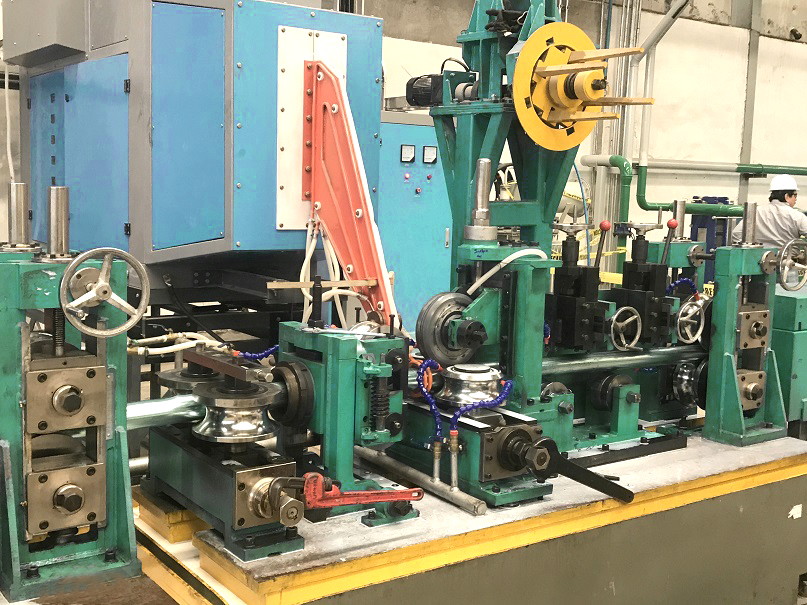

Welded tube production depends on precise and reliable machinery. Efficient steel coil processing equipment forms the backbone of this industry. It transforms raw coils into prepared strips for forming and welding.

High-quality equipment ensures consistent output and reduces waste. International tube mills require robust solutions to meet standards. Brands like SANSO provide advanced systems for these needs.

This article details five essential components. Each plays a vital role in tube manufacturing. Understanding them helps optimize production lines and improve quality.

Decoilers unwind steel coils at the start of the line. Recoilers wind processed strips for storage. These systems ensure continuous material flow.

Proper decoiling prevents jams and delays. It sets the pace for subsequent processes. Modern decoilers handle various coil sizes and weights.

Common decoiler types include:

Mandrel decoilers for heavy coils up to 20 tons.

Double mandrel systems for quick coil changes.

Pneumatic decoilers for lighter materials.

Key features to consider are adjustable tension control and automated loading. Integration with digital controls allows real-time monitoring. This maintains consistent feeding to tube forming stations.

Regular maintenance includes bearing checks and motor inspections. Decoilers are fundamental to steel coil processing equipment. They impact overall line efficiency in welded tube mills.

Leveling machines remove curls and distortions from steel strips. This step is crucial for achieving flat material. Flat strips ensure accurate tube forming and welding.

Uneven material can cause defects in the final product. Levelers use multiple rolls to apply even pressure. The number of rolls depends on material thickness.

Modern levelers incorporate several technologies:

Multi-roll systems for uniform pressure distribution.

Computerized controls for automatic adjustments.

Combination machines that integrate leveling with other processes.

In welded tube manufacturing, leveling ensures strips enter forming stations evenly. Brands like SANSO offer precision levelers with customizable settings. These machines reduce material waste and improve quality.

Maintenance involves cleaning rolls and checking alignments. Proper lubrication extends service life. Leveling is a key function in steel coil processing equipment for tube mills.

Edge trimmers cut steel strip sides to precise widths. This process is vital for welded tube quality. Consistent width reduces welding defects and improves fit.

Trimming systems can be standalone or integrated into the line. They handle various materials, including galvanized steel. Automated trimmers enhance speed and accuracy.

Automated systems offer several advantages:

Accurate width control within tight tolerances.

Reduced material waste through efficient cutting.

Enhanced safety with enclosed cutting mechanisms.

Lower labor costs due to minimal manual intervention.

In tube mills, trimming occurs after leveling. It prepares strips for the forming process. Modern steel coil processing equipment often includes high-speed trimmers.

Maintenance includes blade sharpening and alignment checks. Regular upkeep ensures consistent performance. Edge trimming is essential for high-quality tube production.

Feeding units control strip speed and position. Guiding units keep material aligned during processing. Together, they ensure smooth operation in tube mills.

Misalignment can cause production errors and downtime. Proper feeding and guiding prevent these issues. They are critical for high-speed processing lines.

These units perform several important functions:

Maintaining consistent feed rates to forming stations.

Aligning strips to prevent edge damage.

Integrating with sensors for real-time adjustments.

Feeding systems often use servo motors for precision. Guiding systems may employ hydraulic or pneumatic actuators. They work seamlessly with other steel coil processing equipment.

Regular calibration ensures accuracy. Operators should check for wear on guides and feeders. These units significantly impact tube mill efficiency.

Slitting lines cut wide steel coils into narrower strips. This is done for specific tube dimensions or applications. It adds flexibility to production processes.

Slitting is often performed before tube forming. It allows mills to use standard coil widths for multiple products. This reduces inventory costs and waste.

A typical slitting line includes several key parts:

Uncoiler to feed the master coil.

Slitter head with rotary knives for cutting.

Separator to keep slit strips apart.

Recoiler to wind the processed strips.

Slitting lines require precise knife alignment. Digital controls help maintain cutting accuracy. They are integral to comprehensive steel coil processing equipment setups.

Maintenance involves knife inspection and replacement. Proper setup reduces burr formation. Slitting lines enhance productivity in welded tube manufacturing.

In summary, effective welded tube manufacturing relies on robust steel coil processing equipment. Each component, from decoilers to slitting lines, plays a specific role. Selecting the right equipment improves quality and efficiency.

Brands like SANSO offer reliable solutions for tube mills. Their equipment is designed for durability and precision. For more details, visit their website to explore product options.

Understanding these five components helps operators optimize their lines. Investing in quality steel coil processing equipment leads to better tubes and lower costs. It is a crucial step for any manufacturing facility.

Q1: What is the primary function of steel coil processing equipment in tube mills?

A1: The primary function is to prepare steel coils for forming and welding. This includes decoiling, leveling, trimming, and slitting. Proper processing ensures material meets specifications for tube production.

Q2: How do I choose the right steel coil processing equipment for my tube mill?

A2: Consider factors like coil weight, material thickness, production speed, and integration needs. Assess your mill's space and power requirements. Consulting with suppliers like SANSO can help tailor solutions.

Q3: What maintenance is required for steel coil processing equipment?

A3: Regular maintenance includes lubrication, inspection of wear parts, and calibration of controls. Check decoiler bearings, leveler rolls, and trimmer blades periodically. Proper upkeep extends equipment life and prevents downtime.

Q4: Can steel coil processing equipment be automated?

A4: Yes, many modern systems feature automation for feeding, guiding, and trimming. Automation improves precision, reduces labor costs, and enhances safety. It is common in advanced tube mill setups.

Q5: Where can I find reliable steel coil processing equipment suppliers?

A5: Reliable suppliers include manufacturers with industry experience. Brands like SANSO offer a range of equipment for welded tube manufacturing. Visit their website for product information and support.