In the metal fabrication industry, a steel coil slitting line is crucial for processing raw materials into precise strips. This equipment is widely used in welded tube and pipe production. It ensures efficient material handling and quality output. Brands like SANSO offer reliable solutions in this field.

What is a Steel Coil Slitting Line?

A steel coil slitting line is a machine used to cut wide steel coils into narrower strips. These strips are then used in various manufacturing processes. In welded tube and pipe mills, it prepares material for forming and welding.

The process involves several stages. Each stage ensures precision and consistency. Proper operation reduces waste and improves productivity.

It handles coils of different thicknesses and widths.

Slitting accuracy is vital for downstream applications.

Modern lines include automation for better control.

Understanding this equipment helps in selecting the right steel coil slitting line for your needs.

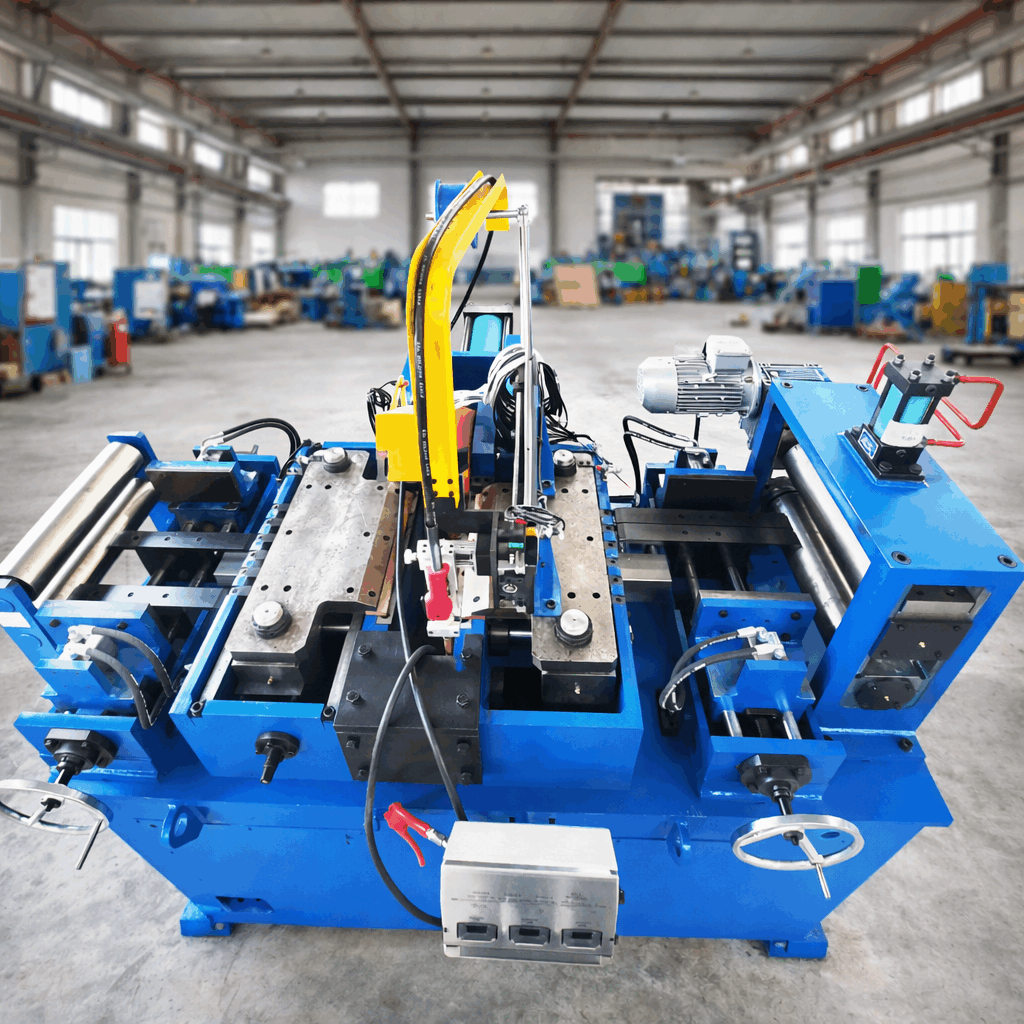

Key Components of a Steel Coil Slitting Line

Each component plays a specific role. Together, they enable efficient slitting operations.

Uncoiler

The uncoiler holds and feeds the steel coil into the line. It must handle heavy weights smoothly. Tension control is critical here.

Slitter Head

This is where the actual cutting occurs. It uses rotary knives to slit the coil. Knife setup affects strip quality and edge condition.

Recoiler

The recoiler winds the slit strips into new coils. It ensures tight and even winding. This prepares strips for further processing.

Other parts include entry and exit guides, scrap choppers, and control systems. A well-designed steel coil slitting line integrates these components seamlessly.

Types of Steel Coil Slitting Lines

Different types cater to varied production requirements. Selection depends on material specs and output goals.

Standard Slitting Lines

These are used for general-purpose applications. They handle mild steel and common alloys. Speed and accuracy are balanced for cost-effectiveness.

High-Speed Slitting Lines

Designed for high-volume production. They feature advanced drives and controls. Such lines reduce cycle times and increase throughput.

Specialized lines exist for stainless steel or coated materials. Consulting experts like SANSO can help choose the right type.

Applications in Welded Tube and Pipe Manufacturing

The steel coil slitting line is fundamental in tube and pipe mills. It provides slit strips that are formed into tubular shapes.

These strips are then welded longitudinally. Precision slitting ensures uniform wall thickness and diameter. This is key for quality pipes used in construction, automotive, and infrastructure.

Produces strips for ERW (Electric Resistance Welding) tubes.

Enables material optimization for large-scale projects.

Supports international standards in pipe manufacturing.

Efficient slitting lines enhance overall mill productivity. They are a core part of modern fabrication setups.

Benefits of Using a Steel Coil Slitting Line

Investing in a reliable slitting line offers multiple advantages. These benefits impact both operational and financial aspects.

Improves material utilization by reducing scrap.

Increases production speed with automated features.

Enhances strip quality for better weld integrity.

Reduces labor costs through streamlined processes.

Allows flexibility in handling various coil sizes.

A well-maintained steel coil slitting line ensures long-term reliability. It supports sustainable manufacturing practices.

How to Choose the Right Steel Coil Slitting Line

Selecting the appropriate line requires careful consideration. Factors include material types, production volume, and space constraints.

First, assess the coil specifications you will process. Thickness, width, and tensile strength matter. Then, determine your desired output speed and accuracy.

Look for features like automatic knife adjustment and tension control. After-sales service and spare parts availability are also important. Brands like SANSO provide tailored solutions.

Finally, consider future needs. A scalable steel coil slitting line can adapt to changing demands. This protects your investment over time.

Maintenance and Safety Considerations

Regular maintenance extends equipment life. It also prevents unexpected downtime. Key practices include lubrication, knife inspection, and alignment checks.

Safety is paramount in operating a steel coil slitting line. Operators should follow protocols for handling coils and tools. Training reduces accident risks.

Schedule routine inspections of critical components.

Use protective gear when near moving parts.

Keep the work area clean and organized.

Proper care ensures consistent performance. It also aligns with industry safety standards.

A steel coil slitting line is indispensable in welded tube and pipe manufacturing. It enables precise material preparation for high-quality end products. Understanding its components, types, and benefits aids in effective implementation.

For reliable equipment, explore options from established providers. SANSO offers expertise in this area, supporting global fabrication needs. Investing in the right slitting line boosts efficiency and competitiveness.

Frequently Asked Questions (FAQ)

Q1: What is the primary function of a steel coil slitting line?

A1: The primary function is to cut wide steel coils into narrower strips. These strips are used in further manufacturing, such as in welded tube and pipe production.

Q2: How does a steel coil slitting line improve production efficiency?

A2: It automates the slitting process, reducing manual handling. This increases speed, minimizes scrap, and ensures consistent strip dimensions for downstream operations.

Q3: What materials can be processed on a steel coil slitting line?

A3: It typically handles mild steel, stainless steel, aluminum, and coated metals. The specific material depends on the line's design and knife configuration.

Q4: What are the key factors when selecting a steel coil slitting line?

A4: Key factors include coil width and thickness, production volume, desired strip width, automation level, and budget. Consulting with suppliers like SANSO can guide the choice.

Q5: How often should maintenance be performed on a steel coil slitting line?

A5: Regular maintenance should be done as per the manufacturer's schedule, often weekly or monthly. This includes checking knives, lubricating parts, and inspecting electrical systems.

Q6: Can a steel coil slitting line be customized for specific needs?

A6: Yes, many manufacturers offer customization. Options may include special knife setups, additional tension controls, or integration with other mill equipment.