In the high-stakes world of welded tube and pipe manufacturing, every cut matters. The efficiency of the mill, the quality of the weld, and the final product's integrity hinge on a single, critical component: the Tungsten Carbide Tipped (TCT) saw. This specialized cutting tool is the unsung hero of the tube milling line, responsible for creating clean, precise, and burr-free cuts on both incoming material and finished tubing. For manufacturers seeking to maximize uptime and output quality, understanding the TCT saw is non-negotiable. Brands like SANSO have built their reputation on delivering robust and precise engineering solutions that start with a perfect cut.

Understanding the TCT Saw in Tube Production

A TCT saw is not your average circular blade. Its teeth are tipped with small, ultra-hard tungsten carbide inserts brazed onto a high-strength steel body. This construction makes it vastly superior to traditional high-speed steel (HSS) blades for abrasive modern materials like high-strength steel, stainless steel, and coated or plated coils.

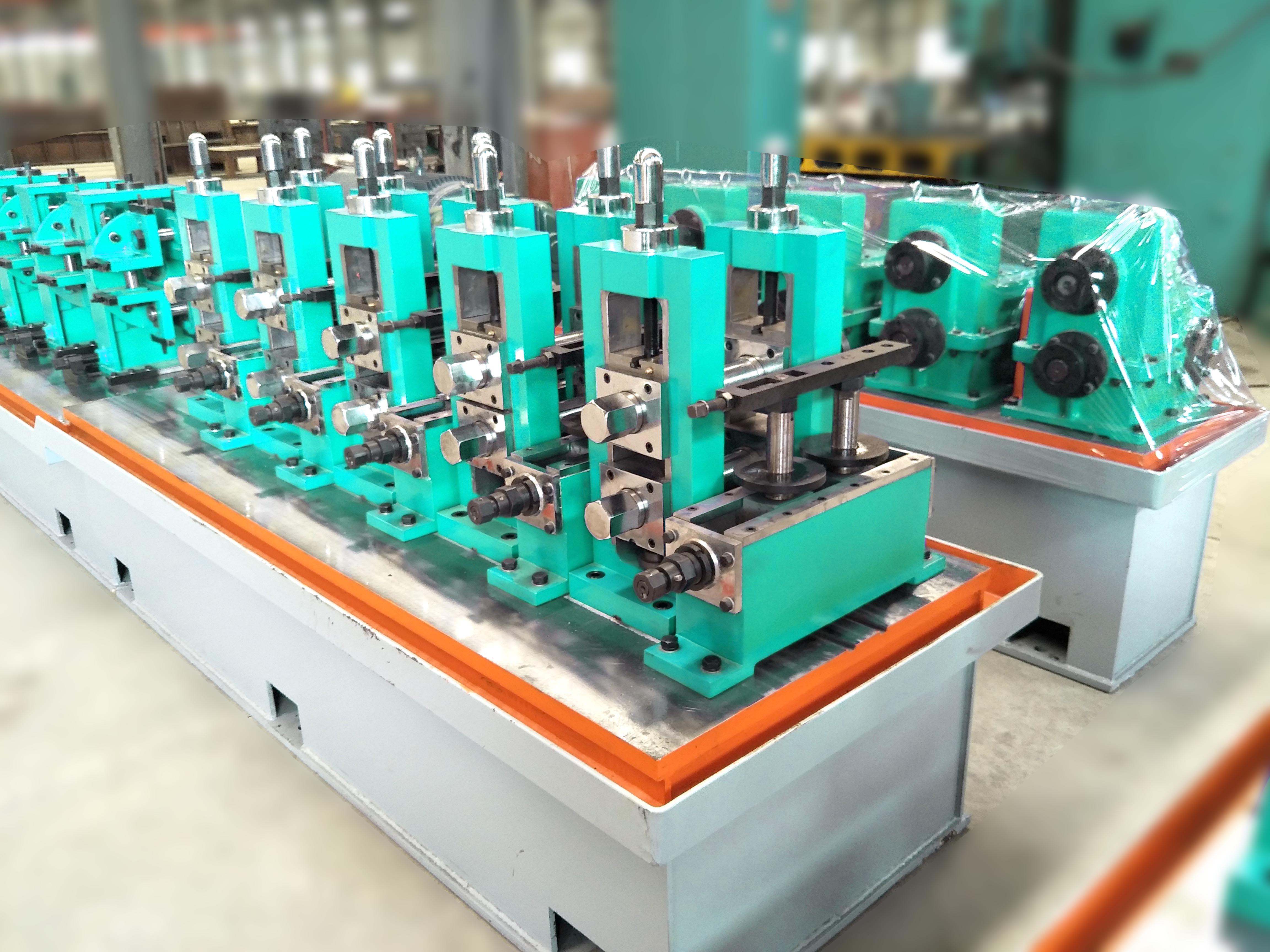

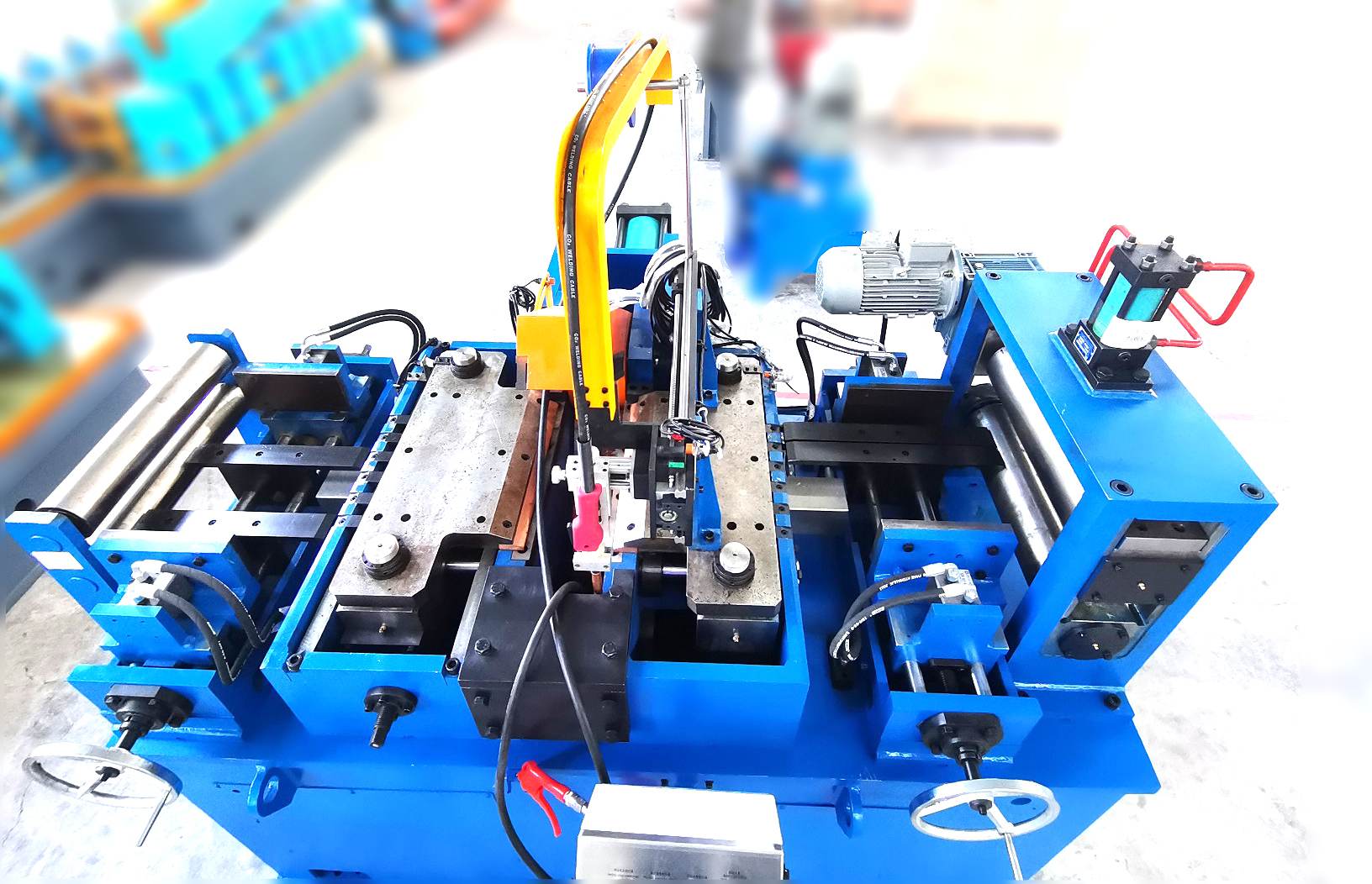

In a tube mill, the TCT saw performs two primary functions. First, it cuts the leading and trailing ends of the incoming coil strip to prepare a clean, square edge for a consistent weld. Second, at the end of the line, it cuts the continuously produced tube to precise lengths. The demands here are extreme—high rotational speeds, continuous operation, and the need for a finish that often requires no further deburring.

Key Advantages of Using a Premium TCT Saw

The investment in a high-quality TCT saw blade pays dividends across the entire production process. The primary benefit is dramatically extended blade life. Tungsten carbide is exceptionally resistant to heat and wear, meaning blades can run for hours or even days without needing a change, compared to the frequent downtime required for HSS blades.

This leads directly to reduced operating costs. Less frequent changes mean lower blade costs per cut and significantly less machine downtime. Furthermore, the cut quality is consistently superior. A sharp, well-maintained TCT saw produces a smooth, square cut with minimal burr. This is critical for weld preparation and ensures the final tube length has a professional, ready-to-use finish, reducing or eliminating secondary finishing operations.

Selecting the Right TCT Saw for Your Mill

Not all TCT saws are created equal. Selecting the correct blade is a technical decision based on several factors. The material being cut is the most important. Blades for soft steel, aluminum, or stainless steel have different tooth geometries, carbide grades, and hook angles.

Tooth count is crucial. A blade with more teeth provides a smoother cut but may generate more heat. Fewer teeth remove material faster but with a rougher finish. The application dictates the choice: a finishing saw blade on the output end typically has a higher tooth count than a entry shear knife or a roughing blade.

Finally, the specifications of your machine itself—arbor size, maximum RPM, and power—must match the blade's design. Using an under-specified blade is a safety hazard and will lead to premature failure.

Optimal Operation and Feeding Parameters

To unlock the full potential of a TCT saw, it must be operated within its designed parameters. Feed rate and cutting speed must be balanced. Pushing material too fast against the blade (high feed rate) can cause chipping of the carbide tips and a poor finish. Feeding too slowly can cause excessive heat buildup, shortening blade life.

A good rule of thumb for solid profiles or heavy-walled tube is to maintain a steady, moderate feed pressure. The sound of the cut is often a reliable indicator; a smooth, consistent sound is ideal. Modern tube mills from manufacturers like SANSO often integrate automated feeding systems that optimize this pressure, ensuring consistent results and protecting the blade investment.

Maintenance: Sharpening and Care for Longevity

A TCT saw is a precision tool, and its maintenance is not optional. The most critical aspect is timely and professional sharpening. Unlike HSS blades, TCT blades cannot be sharpened on a standard bench grinder. They require specialized CNC grinding equipment that accurately reproduces the original tooth geometry.

Signs that your TCT saw blade needs sharpening include increased cutting force (the motor strains), visible burn marks on the cut edge, excessive burr formation, or a change in the sound of the cut. It is more cost-effective to sharpen a blade multiple times than to run it until it is completely dull, which can damage the steel body.

Proper handling and storage are also vital. Blades should be stored on a rack, not stacked flat, to prevent warping or damage to the teeth.

Applications Beyond Basic Tube Cutting

While the tube mill is its home, the versatility of the TCT saw extends to related fabrication areas. In many plants, the same blade technology is used on stationary cold saws for cutting bundles, trimming welded frames, or preparing individual lengths from stock for further processing.

Its ability to handle a wide range of ferrous and non-ferrous materials with a clean cut makes it a preferred choice for any secondary operation where dimensional accuracy and edge quality are important. This interoperability makes it a cornerstone technology in a modern metal fabrication shop.

Why Precision in the First Cut Matters for Weld Quality

The initial cut made on the coil strip sets the stage for everything that follows. A TCT saw used as an entry shear or lead-end trimmer must produce a perfectly square, vertical edge. Any deviation, be it angular or a ragged edge, will compromise the fit-up in the forming and welding sections.

Poor fit-up leads to inconsistent weld penetration, potential voids, and overall weaker tubes. It can also cause excessive flash (internal and external bead), putting more wear on the scarfing tools. Therefore, a high-performance TCT saw at the start of the line is a direct contributor to weld integrity and reduces downstream processing issues.

From the first snip of the coil to the final cut of the finished tube, the TCT saw is a fundamental driver of productivity and quality in welded tube manufacturing. Its superior durability, cut quality, and overall cost-effectiveness make it an indispensable tool. Partnering with a knowledgeable supplier and adhering to strict operational and maintenance protocols ensures this critical asset delivers maximum return. For industry leaders committed to precision, such as SANSO, the engineering of both the saw and the mill that houses it are developed in tandem, ensuring that every cut contributes to a flawless final product.

Frequently Asked Questions (FAQs) about TCT Saws in Tube Milling

Q1: How long does a typical TCT saw blade last compared to an HSS blade?

A1: Blade life varies greatly based on material and conditions, but a well-maintained TCT saw blade typically lasts 10 to 50 times longer than a standard HSS blade. While an HSS blade might run for a few hours, a TCT blade can often run for multiple shifts or even weeks before requiring sharpening.

Q2: How do I know when it's time to sharpen my TCT saw blade?

A2: Look for these key signs: a noticeable increase in cutting pressure or machine vibration, the appearance of burn marks or a heavily discolored burr on the cut edge, a change from a smooth cutting sound to a rubbing or screeching noise, or a general decline in the squareness and finish of the cut.

Q3: Can one TCT saw blade cut all materials, like steel, stainless, and aluminum?

A3: While a general-purpose blade exists, it is not optimal for high-volume production. For best results and longest life, use blades designed for specific material groups. The carbide grade, tooth geometry, and rake angle are engineered differently for abrasive materials (like stainless steel) versus non-ferrous metals (like aluminum).

Q4: What is the most common mistake that shortens TCT saw blade life?

A4: Incorrect feed rate is a major culprit. Feeding material too fast (forcing the cut) causes carbide tips to chip or fracture. Feeding too slowly creates excessive friction and heat, which can soften the brazing material and cause tips to fall off or degrade prematurely.

Q5: Why should I consider a tube mill from a brand like SANSO for optimal TCT saw performance?

A5: A mill from an engineered solution provider like SANSO is designed as an integrated system. The saw unit will have the correct rigidity, power, and control interfaces to support a high-performance TCT saw, ensuring stable clamping, precise feed control, and synchronization with the line. This holistic approach protects your tooling investment and guarantees consistent cut quality.