Machine coolant filtration is a key process in welded tube manufacturing. It keeps coolant clean and effective for tube milling operations.

Clean coolant helps machines run smoothly and extends tool life. In international welding and tube milling, this filtration is essential for quality control.

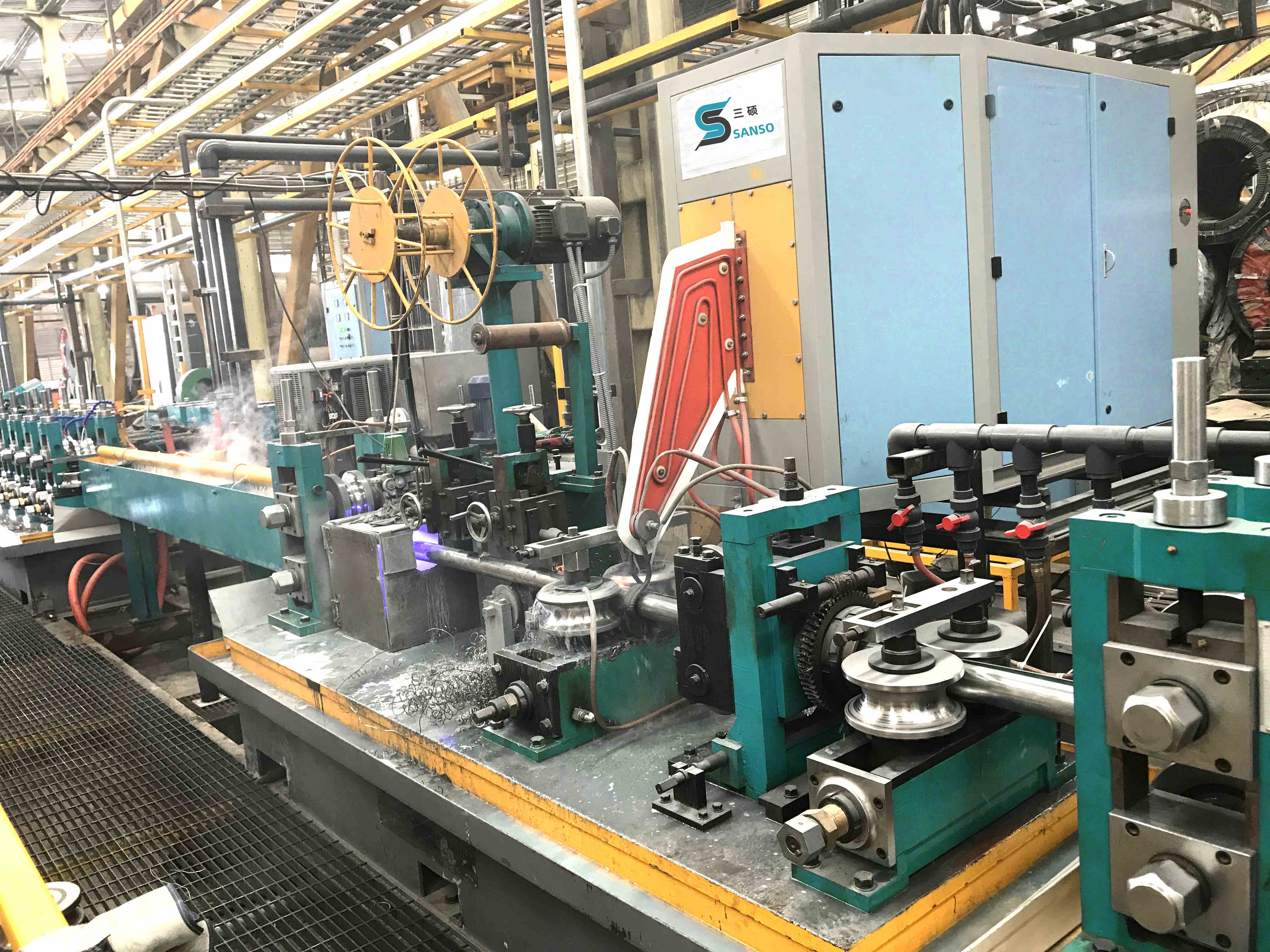

Companies like SANSO provide specialized systems for this purpose. Effective machine coolant filtration reduces downtime and costs.

In welded tube production, coolants are used to lubricate and cool cutting tools. They prevent overheating during milling.

Without proper machine coolant filtration, contaminants build up. This leads to poor performance and defects in tubes.

Coolants can collect metal chips, dirt, and oils. These contaminants cause issues in tube milling.

Scratches or marks on tube surfaces

Inaccurate cuts and dimensions

Increased wear on milling tools

Risk of corrosion in finished tubes

Machine coolant filtration removes these particles. It ensures consistent quality in welded tube outputs.

Different filtration methods suit various needs in tube manufacturing. Choosing the right system is crucial.

Effective machine coolant filtration depends on technology and application. SANSO offers a range of systems for diverse milling environments.

Several technologies are used in machine coolant filtration. Each has its own advantages.

Media Filtration: Uses filter paper or cloth to trap particles. Good for fine contaminants.

Centrifugal Separation: Spins coolant to separate solids by density. Effective for heavy debris.

Magnetic Filtration: Uses magnets to remove ferrous particles. Ideal for steel tube milling.

Vacuum Filtration: Draws coolant through a filter under vacuum. Suitable for high-precision applications.

Selecting a system depends on coolant type and contamination level. Regular assessment helps maintain efficiency.

Implementing machine coolant filtration brings multiple advantages. It supports international standards in tube production.

Clean coolant improves overall milling performance. This leads to better products and lower operational costs.

Filtered coolant reduces abrasion on cutting tools. Tools last longer and require fewer replacements.

Machines run with less strain, lowering energy use. This boosts productivity in tube milling lines.

For example, systems from SANSO help maintain optimal coolant conditions. This prolongs equipment lifespan.

Clean coolant ensures precise cuts and smooth finishes on tubes. It minimizes defects in welded seams.

Consistent quality meets customer expectations. It also reduces waste and rework in manufacturing.

Machine coolant filtration is vital for high-tolerance tube milling. It aligns with global quality benchmarks.

Setting up machine coolant filtration requires planning. It involves integration with existing milling equipment.

Proper installation ensures seamless operation. Training staff on maintenance is also important.

Follow these steps to implement filtration in tube milling:

Assess coolant contamination levels and flow rates

Choose a filtration system that matches mill capacity

Install the system inline with coolant pumps and tanks

Test for leaks and performance adjustments

Monitor output and make improvements as needed

Brands like SANSO offer support for integration. Their systems are designed for easy setup in industrial environments.

Regular maintenance keeps machine coolant filtration effective. Neglect can lead to system failures.

Important maintenance tasks include:

Cleaning or replacing filters on schedule

Checking for clogs and pressure drops

Inspecting seals and connections for wear

Testing coolant quality periodically

A well-maintained system ensures reliable performance. It supports continuous tube production.

Tube milling environments pose specific challenges for filtration. Addressing them improves outcomes.

Common issues include high contaminant loads and chemical breakdown. Machine coolant filtration systems must handle these.

Welded tube milling generates many metal chips. Filtration systems need high capacity.

Using multi-stage filtration can help. For instance, combine magnetic and media filters for better results.

Regular system checks prevent overloads. This maintains coolant clarity.

Coolants can break down over time due to heat and use. Filtration alone may not fix this.

Adding coolant management practices is key. This includes monitoring pH levels and adding additives.

Effective machine coolant filtration works with these practices. It extends coolant life and reduces disposal needs.

Innovations are shaping machine coolant filtration. New technologies aim for higher efficiency and sustainability.

Trends include smarter sensors and automation. These help in predictive maintenance and real-time monitoring.

In welded tube milling, such advances can reduce waste. They align with environmental regulations.

Companies like SANSO are investing in these technologies. Their systems may incorporate IoT for better control.

Machine coolant filtration is a cornerstone of modern welded tube manufacturing. It ensures quality, efficiency, and cost savings.

By implementing robust filtration systems, mills can improve their operations. This meets international standards for tube production.

Brands like SANSO provide reliable solutions for this need. As technology evolves, machine coolant filtration will continue to be vital.

Q1: What is machine coolant filtration in tube milling?

A1: Machine coolant filtration is the process of removing contaminants from coolant used in welded tube milling. It keeps the coolant clean for effective lubrication and cooling.

Q2: Why is machine coolant filtration important for welded tube quality?

A2: It prevents defects like scratches and inaccuracies in tubes. Clean coolant ensures precise cuts and smooth finishes, meeting quality standards in manufacturing.

Q3: What types of filtration systems are common?

A3: Common types include media filtration, centrifugal separation, magnetic filtration, and vacuum filtration. Each suits different contamination levels and milling needs.

Q4: How often should filtration systems be maintained?

A4: Maintenance frequency depends on usage, but generally, filters should be checked weekly. Regular cleaning and replacement prevent system failures.

Q5: Can machine coolant filtration reduce operational costs?

A5: Yes, it reduces costs by extending tool life, lowering energy use, and minimizing waste. Effective filtration also cuts down on coolant replacement and disposal expenses.