If you run a tube mill, you know downtime is expensive. The cutting station is where everything comes together, and the choice of blade can make or break your shift. For many fabricators worldwide, the HSS circular blade is the reliable workhorse that keeps production moving. Getting the most out of these blades isn't just about buying them; it's about understanding them. Knowing a few key facts can stretch their life, improve your cut quality, and save real money. This is where experience from trusted suppliers like SANSO becomes invaluable on the shop floor.

Let's break down the name. HSS stands for High-Speed Steel. This isn't your ordinary steel. It's a special alloy cooked up with tungsten, molybdenum, chromium, and often cobalt. These elements give it a superpower: it stays hard even when the cutting edge gets red-hot from friction.

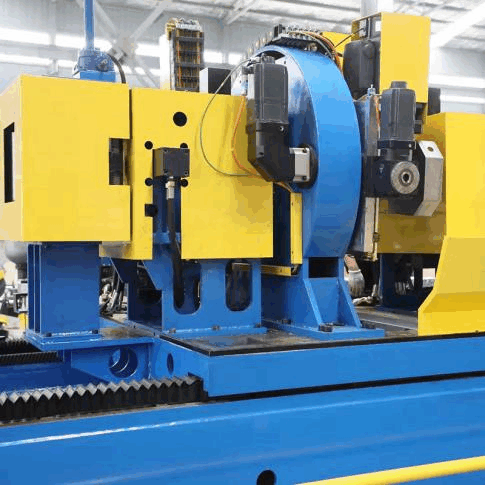

A HSS circular blade is a disc made from this material, with teeth cut or ground into its edge. In tube milling, these blades are mounted on cold saws or similar cut-off machines. They spin at high speeds to cleanly sever lengths of welded tube after forming. Their ability to take the heat and keep cutting is why they're still so popular.

In the fast-paced environment of tube production, predictability matters. HSS circular blades offer a solid balance that plant managers appreciate.

First is toughness. Welded tube can have inconsistencies—a slight weld flash, variable wall thickness. An HSS blade can handle these minor interruptions without chipping a tooth, which is a real risk with harder, more brittle alternatives.

Second is cost. The initial price is manageable, and the real savings come with re-sharpening. A single HSS circular blade can be professionally re-sharpened many times, making the cost-per-cut extremely competitive. For operations cutting a mix of materials—from basic carbon steel to some lower-alloy grades—this versatility and economy are hard to beat.

You wouldn't use a wood saw to cut metal. Similarly, not every HSS circular blade is right for every tube. The tooth geometry—the shape, angle, and spacing of the teeth—is precisely engineered.

Using the wrong geometry leads to poor finishes, excessive burr, and fast blade wear. It’s the first thing a good technician like those at SANSO will ask about when troubleshooting a cut quality issue.

Think of coolant as an essential component of the HSS circular blade system. Its job goes beyond just cooling.

Yes, it prevents the blade and workpiece from overheating, which softens the HSS. But it also lubricates the cut, reducing the power needed. Most importantly in tube cutting, it floods the teeth and washes away chips. If chips weld onto the teeth (chip welding), they ruin the cutting edge instantly.

A good coolant mixture, directed properly at the point of cut, can double or triple blade life. It’s that important.

An experienced operator can diagnose a cut by listening and watching. A smooth, consistent hiss usually means all is well. A rough, chattering sound or a change in the motor pitch often signals a problem.

It could be a dull blade, incorrect feed speed, or a loose clamp. A sharp HSS circular blade should cut with minimal pressure. If you see the machine laboring or the tube deforming before the cut, it’s time to stop and check. This hands-on awareness prevents minor issues from becoming broken blades or scrapped product.

Sending a blade out for re-sharpening isn't an admission of defeat; it's standard maintenance. However, not all sharpening services are equal.

A proper re-sharpen doesn't just put an edge back on. It restores the original tooth profile and rake angles. This requires skilled technicians and specialized CNC grinding equipment. A bad sharpen that changes the geometry will make the blade perform worse than when it was dull.

Establish a relationship with a reputable sharpening service, often provided by the blade manufacturer itself. A well-maintained HSS circular blade from a quality source should withstand many sharpening cycles.

You can buy the best HSS circular blade on the market, but it will fail quickly on a poorly maintained machine. Three machine factors are non-negotiable:

A quick pre-shift check of clamps, guides, and blade mounting can avoid a world of trouble. Sometimes, the best blade investment is preceded by an investment in machine maintenance.

Selecting the right HSS circular blade comes down to your specific recipe: your primary tube material, wall thickness, diameter, and desired production speed. It's a balance of material science and practical shop floor experience.

This is where partnering with an application-focused supplier pays off. Brands like SANSO don't just sell a box of blades. They provide the technical data, the parameter recommendations, and the on-the-ground insight to match the tool to your job. In the competitive world of tube production, that partnership is a tangible advantage, ensuring your cutting station is a point of reliability, not a bottleneck.

Q1: How often should I expect to re-sharpen my HSS circular blade?

A1: There's no fixed hour count. It depends on material abrasiveness, feed rates, and coolant use. Watch for signs: increased burr, a finished cut that looks "torn" instead of sheared, more sparking, or the machine needing more force. It's better to sharpen a little early than to run a blade until it's completely destroyed.

Q2: Can I use one HSS circular blade to cut both steel and aluminum tube?

A2: Technically yes, but it's not ideal. Cutting aluminum requires a very different tooth geometry (usually a higher, more positive hook angle) to prevent material from gumming up the teeth. For mixed production, a dedicated blade for each material family will give far better results and longer life for both.

Q3: What causes "premature dulling" where a blade loses its edge after very few cuts?

A3: This is almost always a heat issue. The most common culprits are (1) Feed rate too high, (2) Cutting speed (RPM) too low, (3) Inadequate or poorly directed coolant, or (4) Cutting a material much harder than the blade is rated for (e.g., trying to cut stainless with a standard HSS grade).

Q4: I see small chips missing from the teeth. What happened?

A4: This is called chipping. It's usually caused by an impact. This can happen from a loose tube clamp (the tube shifts and pinches the blade), feeding the blade into the tube too aggressively (jerky feed), or hitting a hard inclusion in the steel (like a weld nugget or hardened scale).

Q5: What's the real difference between a mid-price and a premium HSS circular blade like those from SANSO?

A5: The difference is in consistency and total cost-per-cut. Premium blades use higher-grade, more consistent HSS alloys (like M2 or M35 cobalt steel), have more precise heat treatment for uniform hardness, and feature laser-cut or finely ground teeth for perfect balance. They last longer between sharpens, can be re-sharpened more times, and produce more consistent cuts, reducing scrap. The initial price is higher, but the total cost over the blade's life is often lower.