In the world of welded tube and pipe manufacturing, every second of downtime and every millimeter of material waste cuts into profit. The process starts long before the forming rolls and welding head engage—it begins at the coil. This is where the reel uncoiler proves its worth. Often considered a simple piece of auxiliary equipment, a well-chosen reel uncoiler is, in fact, a foundational component for stability, efficiency, and quality. For manufacturers worldwide, selecting the right reel uncoiler is a critical decision that impacts the entire production line. Established brands like SANSO have built their reputation on delivering robust and reliable uncoiling solutions that meet these rigorous demands.

A reel uncoiler, sometimes simply called an uncoiler or decoiler, is the machine that holds and systematically unwinds a coil of metal strip. It serves as the material feeder for the subsequent stages of a tube mill or slitting line.

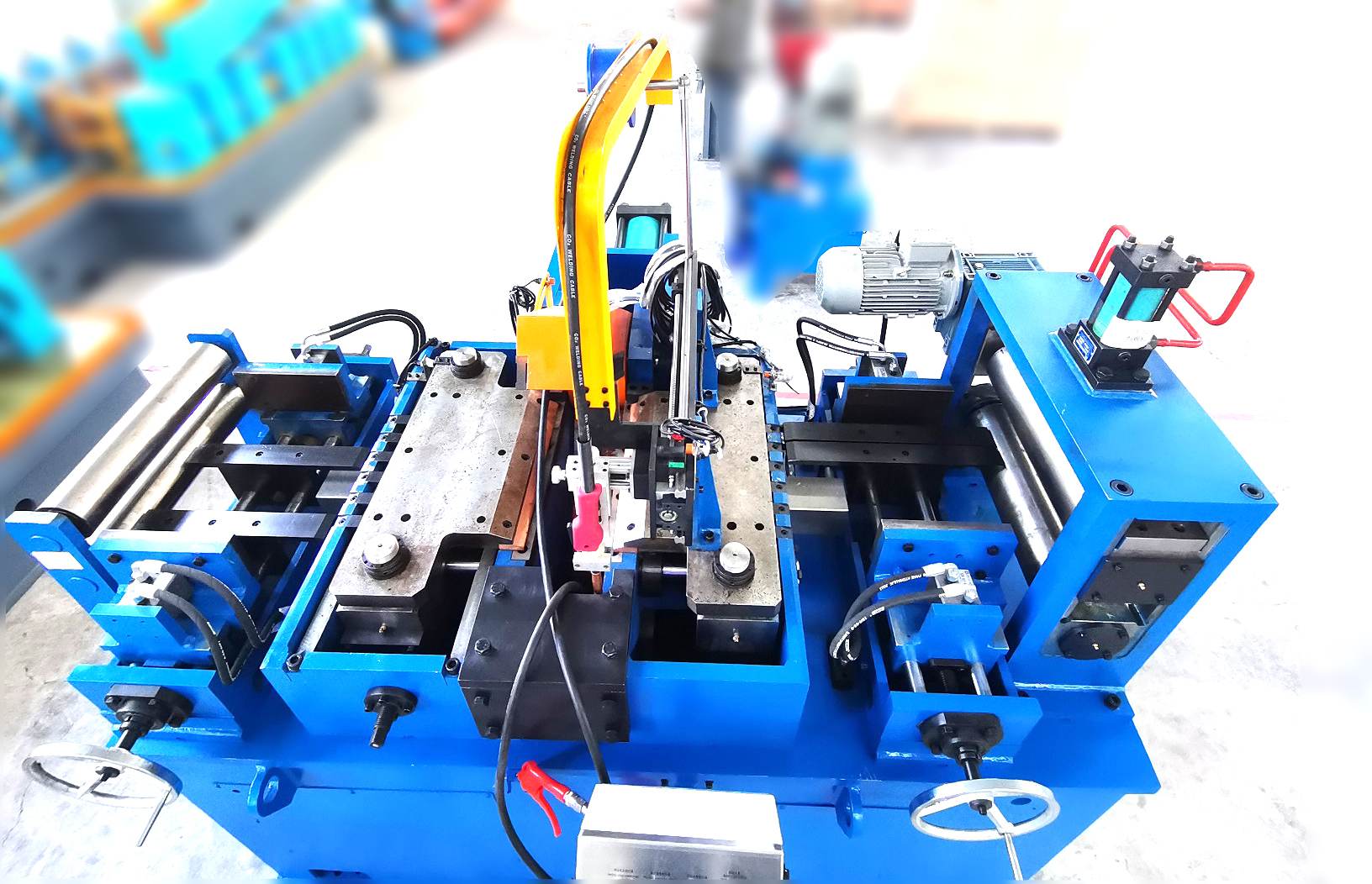

The core function is straightforward but precision-dependent. A heavy-duty, expandable mandrel is inserted into the coil's inner diameter. Once expanded to grip the coil securely, the machine allows the strip's leading end to be threaded into the next station. The reel uncoiler then controls the pay-off of the material, either passively through a drag brake or actively via a powered drive, maintaining consistent tension as the coil diminishes in size.

Key Benefits of a Quality Reel Uncoiler

Why does the uncoiler deserve more attention? The benefits are tangible and directly affect operational metrics.

Ensures Consistent Material Flow

A primary role of the reel uncoiler is to provide a smooth, steady feed of strip. Any hiccup, jerk, or loop formation here causes immediate problems downstream. Consistent flow is non-negotiable for maintaining proper alignment into the leveler and forming section.

Protects Material and Product Quality

An uncoiler with proper tension control prevents the strip from scraping against itself or the machine frame. This minimizes surface scratches and edge damage on pre-finished or sensitive materials. Protecting the strip at this first stage preserves the quality of the final welded tube.

Increases Overall Line Efficiency

Quick and safe coil loading is vital. Modern reel uncoiler designs incorporate hydraulic mandrels, coil carts, and peelers to dramatically reduce changeover time. Faster coil changes mean less downtime and higher overall equipment effectiveness (OEE) for the mill.

Enhances Operational Safety

Handling multi-ton steel coils is inherently hazardous. A well-designed reel uncoiler mechanizes the most dangerous steps. Features like powered cone movement, integrated brakes, and stable framing protect operators from manual strain and crushing risks.

Common Types of Reel Uncoilers in Tube Manufacturing

Not all uncoilers are the same. The choice depends on coil specifics, material type, and line speed.

Single Mandrel Uncoilers

This is the most common design. It holds one coil at a time. It can be "dead" (non-powered with a brake) or "motorized" (power-assisted). The motorized version, often crucial for heavier coils or high-speed lines, provides active, synchronized feed control.

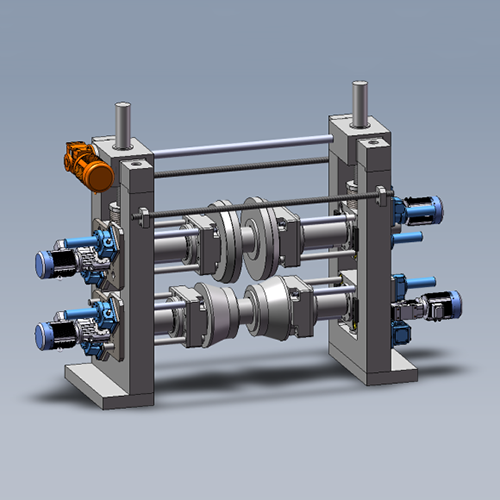

Double Mandrel or Rotary Head Uncoilers

For maximum productivity with minimal stoppage, this type holds two coils. While one is feeding the line, the other can be loaded and prepped. Once the first coil runs out, the head rotates to seamlessly start the second coil, enabling near-continuous operation.

Portable or Light-Duty Uncoilers

These are used for lighter coils, narrower strips, or more flexible materials like certain aluminum or thin-gauge steels. They offer flexibility and are often used in smaller fabrication shops or for pilot lines.

Critical Applications in Welded Tube and Pipe Production

The reel uncoiler is versatile, serving as the entry point for various critical processes.

High-Speed ERW Tube Mills

For electric resistance welding lines producing conduit, structural tube, or mechanical tubing, a heavy-duty, motorized reel uncoiler is often essential. It manages the high inertia of large coils and provides the steady tension needed for a consistent weld.

Precision Pipe Mills for Pressure Applications

Manufacturing pipes for hydraulic or structural purposes requires impeccable material handling from the start. Any defect introduced at the uncoiling stage can compromise the pipe's integrity. A precision reel uncoiler with advanced guiding is key.

Slitting Lines Feeding Multiple Tube Mills

Many operations use a central slitting line to process master coils into narrower strips. The reel uncoiler at the head of this line must handle the widest and heaviest coils, providing flawless feed to ensure clean, burr-free slit edges—a prerequisite for quality welding later.

Integration with Tube Mill Automation

Modern smart factories demand connectivity. Today's advanced reel uncoiler can be integrated into the mill's main PLC, providing data on coil weight, remaining length, and maintenance alerts. This integration is a step toward full Industry 4.0 implementation.

How to Select the Right Reel Uncoiler for Your Operation

Choosing an uncoiler requires careful evaluation of your specific needs. Here are the key factors.

Coil Specifications: The Starting Data

You must know your maximum and typical coil dimensions: Inner Diameter (ID), Outer Diameter (OD), width, and maximum weight. The reel uncoiler must be rated to handle your heaviest coil safely.

Material Characteristics

The type of material (mild steel, high-strength steel, aluminum, pre-painted) influences the choice. Tension control needs, mandrel surface (to prevent marking), and machine rigidity all vary with material.

Power and Drive Requirements

Will a non-powered, brake-controlled uncoiler suffice, or does your line speed and coil weight demand a powered, motorized feed system? High-speed lines almost always require the positive drive of a motorized reel uncoiler.

Mandrel Design and Expansion

The mandrel must grip the coil ID securely without causing deformation. Hydraulic expansion mandrels offer powerful, even gripping force. The expansion range must cover all your standard coil IDs.

Essential Features and Accessories

Consider add-ons that boost productivity: a motorized coil car, automatic edge guidance (EGU), hydraulic peelers to lift the strip lead, and sturdy looping pits for tension management. These features, commonly engineered into SANSO uncoilers, turn a basic machine into a high-performance asset.

The journey to producing high-quality welded tube begins with the first revolution of the coil. Neglecting the importance of a reliable reel uncoiler can lead to a cascade of problems—poor tension, material damage, frequent stoppages, and compromised weld integrity. It is an investment in the stability of your entire manufacturing process. By carefully matching the machine's capabilities to your production requirements, you lay a solid foundation for efficiency and quality. As technology advances, partnering with experienced manufacturers like SANSO ensures access to reel uncoiler solutions designed for the challenges of modern tube production, helping you stay competitive in the international market.

Frequently Asked Questions (FAQs)

Q1: What is the difference between a "reel uncoiler" and a "decoiler"?

A1: In the tube and sheet metal industry, the terms are often used interchangeably. Both refer to equipment that holds and unwinds a coil. "Reel uncoiler" is perhaps more descriptive of the function, while "decoiler" is a common shorthand. The key is to focus on the machine's specifications, not the name.

Q2: Why would I need a motorized reel uncoiler instead of a non-powered one?

A2: A motorized reel uncoiler actively feeds the strip forward using a drive motor. This is crucial for maintaining precise tension with heavy coils, high-strength materials, or when running at very high line speeds. It prevents the downstream mill from having to "pull" the entire coil weight, which can cause tension spikes and strip damage.

Q3: How do I prevent the coil from "springing" open or tangling when it starts on the uncoiler?

A3: This is called "coil breakout" or "cobbling." It's prevented by using a reel uncoiler equipped with a peeler/straightener arm (or peelers) that physically holds down the first few wraps of the coil. A tension brake is also gradually released in a controlled manner to allow a smooth, controlled start.

Q4: What routine maintenance does a reel uncoiler require?

A4: Regular maintenance includes checking and greasing all bearings (especially the mandrel support bearings), inspecting hydraulic hoses and fittings for leaks, ensuring the mandrel expansion mechanism works smoothly, and verifying that all safety guards and brakes are functional. Always follow the manufacturer's recommended schedule.

Q5: Can a standard reel uncoiler handle both steel and aluminum coils?

A5: It can, but with considerations. Aluminum is softer and more easily marked. You may need a mandrel with protective sleeves or pads. Tension control also needs to be more precise, as aluminum is more prone to stretching. It's best to consult with your supplier, like SANSO, about your intent to process different materials.