In the high-stakes world of international welded tube and pipe milling, efficiency isn't just a goal—it’s a requirement for survival. At the heart of a smooth, productive line lies the often-underestimated component: the motorized decoiler. This isn't just a simple holder for coils; it's the critical starting point that dictates the stability, speed, and quality of the entire downstream process. For manufacturers seeking to minimize downtime and maximize output, understanding and investing in a robust motorized decoiler is non-negotiable. Brands like SANSO have long recognized this, engineering solutions that address the core challenges of modern tube mills.

How Does a Motorized Decoiler Work?

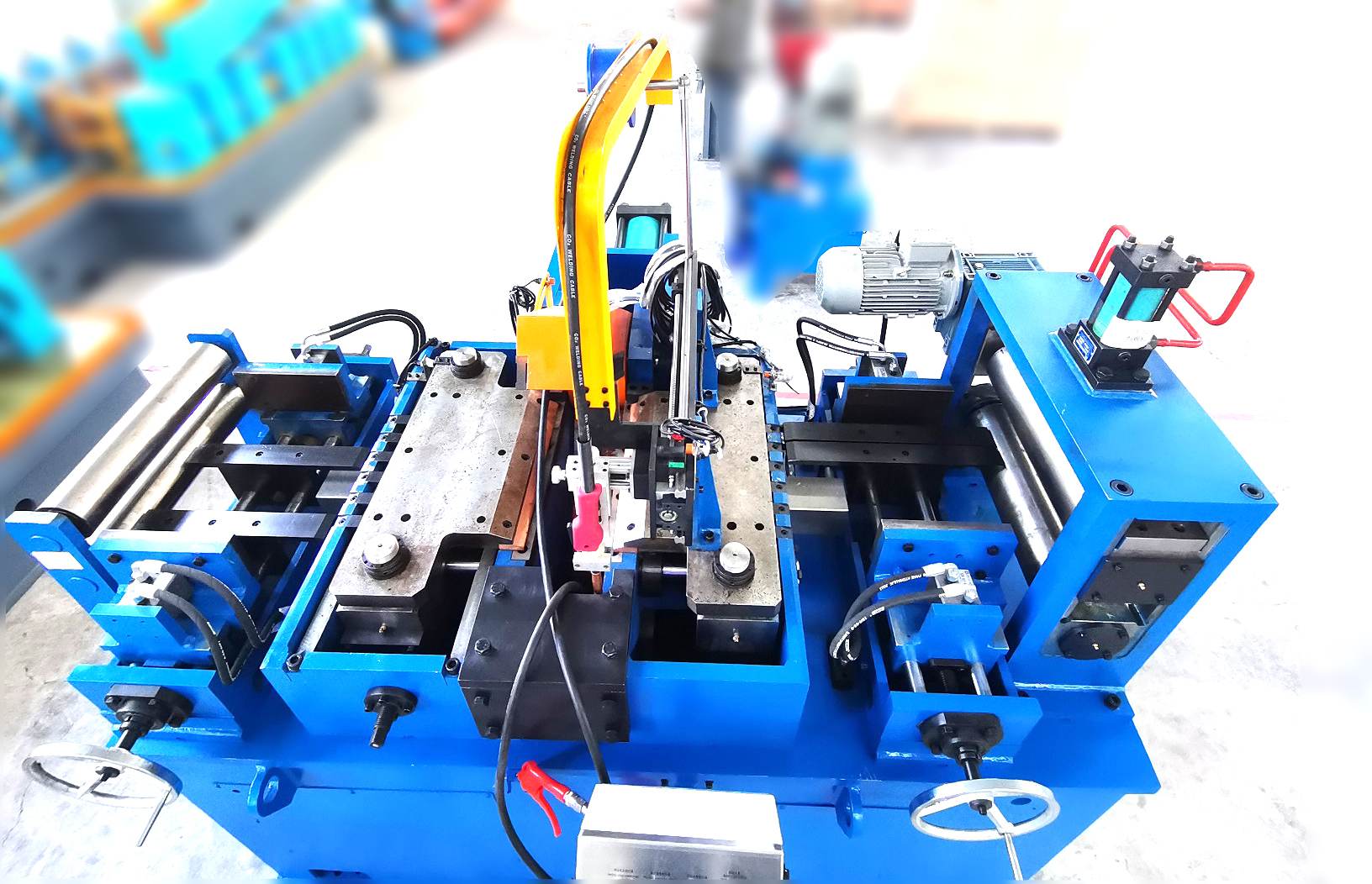

A motorized decoiler is an electrically or hydraulically powered machine designed to hold and actively unwind large, heavy coils of metal strip. Unlike passive, non-powered decoilers that rely on the pull of the mill itself, a motorized decoiler uses its own drive system to feed material forward. This controlled pay-off is synchronized with the speed of the forming and welding stations.

The core components include a heavy-duty mandrel that expands to grip the coil from the inside, a sturdy frame to bear immense weight, and a precision motor system. An integral tension control system, often employing a brake or back-tension mechanism, ensures the strip is fed smoothly without loops or excessive drag, preventing material scarring or deformation.

Key Advantages of Using a Motorized Decoiler in Your Mill

Why should a tube mill operator choose a motorized decoiler over simpler alternatives? The benefits directly impact the bottom line.

Superior Tension Control and Material Handling

Constant, precise tension is paramount. A motorized decoiler provides this by actively managing the unwinding process. This eliminates sudden jerks, slippage, or loop formation, which can cause scratches, edge damage, or variations in strip geometry. Consistent tension leads to a more stable weld and uniform final product.

Increased Production Line Speed

Because the decoiler assists in feeding the strip, it reduces the pulling force required by the forming stations. This allows the entire line to run at higher speeds without the risk of stretching or deforming the material at the infeed stage. It effectively removes a major bottleneck.

Reduced Operator Intervention and Safer Operation

Loading a multi-ton coil is a safety-critical task. Modern motorized decoiler designs often incorporate features like hydraulic mandrel expansion, powered cone cars, and coil lift assists. This minimizes manual handling, reduces the risk of workplace injuries, and speeds up coil changes, boosting overall equipment effectiveness (OEE).

Compatibility with Advanced Automation

In today’s Industry 4.0 landscape, a motorized decoiler is a smart component. It can be integrated into central PLC systems for synchronized speed control, provide data on remaining coil length, and interface with automated guided vehicles (AGVs) for coil logistics. This level of integration is essential for lights-out manufacturing aspirations.

Applications in Welded Tube and Pipe Manufacturing

The motorized decoiler is versatile, serving various critical roles across different mill types.

Precision ERW (Electric Resistance Welding) Tube Mills

For producing structural tubes, mechanical tubing, and conduit, consistent strip feed is vital for a clean, strong weld. A motorized decoiler ensures the strip enters the forming rolls perfectly aligned and under optimal tension.

High-Speed Longitudinal Seam Welding Lines

In applications for pressure pipes or large-diameter tubing, where material thickness and coil weight are significant, the controlled power of a motorized decoiler is indispensable. It manages the heavy payload without introducing instability.

Slitting and Feed Lines Preceding Tube Mills

Many operations first slit wider master coils into narrower strips. A motorized decoiler at the head of a slitting line guarantees a smooth, tension-controlled feed into the slitter, directly impacting the quality of the slit edges that will later be welded.

Choosing the Right Motorized Decoiler: A Guide for Manufacturers

Selecting a motorized decoiler is not a one-size-fits-all decision. Key specifications must align with your production needs.

Coil Weight and Dimension Capacity

This is the primary consideration. The decoiler must be rated for the maximum coil weight (e.g., 10, 20, or 50 tons) and internal/outer diameter you plan to process. Overloading is a severe safety hazard.

Mandrel Type and Expansion Range

The mandrel must securely grip the coil’s inner diameter (ID). Common types include mechanical wedge or hydraulic expansion mandrels. Its expansion range must match your typical coil IDs.

Power and Drive System

The motor’s torque and control responsiveness must handle your material’s width, thickness, and yield strength. Modern AC vector drives offer excellent speed and torque control for sensitive materials.

Integrated Features

Consider add-ons like a coil car, peeler/straightener arms, edge guidance systems (EGUs), and programmable logic controller (PLC) interfaces. These features, often found in premium offerings from manufacturers like SANSO, dramatically enhance functionality and reduce changeover time.

In the competitive arena of international welded tube and pipe manufacturing, optimizing every segment of the production line is crucial. The motorized decoiler, as the active starting point, plays a disproportionately large role in determining overall efficiency, product quality, and operational safety. It is far more than a passive piece of equipment; it is a driver of productivity. Investing in a well-engineered motorized decoiler from a proven supplier is an investment in the stability and profitability of your entire operation. As industry leaders like SANSO continue to innovate in this space, the capabilities of these essential machines will only grow, further solidifying their role as a cornerstone of modern tube mill technology.

Frequently Asked Questions (FAQs)

Q1: What is the main difference between a motorized and a non-motorized (dead) decoiler?

A1: A motorized decoiler has an active drive system (electric or hydraulic) that positively feeds the strip forward, providing controlled tension. A non-motorized, or "dead," decoiler relies solely on the pulling force from the downstream mill, which can lead to uneven tension, strip snatching, and potential material damage.

Q2: How important is tension control on a motorized decoiler for weld quality?

A2: It is absolutely critical. Inconsistent strip tension causes variations in the strip's feed into the forming rolls. This can lead to misalignment, poor edge matching at the weld point, and ultimately, a weak or defective weld seam. Precise tension from a motorized decoiler is foundational for consistent, high-quality welding.

Q3: Can a motorized decoiler handle different coil sizes?

A3: Yes, but its capability depends on the specific machine's design. Key factors are the mandrel's expansion range (to fit different inner diameters) and the width of the supporting arms or cones. When specifying a motorized decoiler, you must provide your expected range of coil IDs, ODs, and weights to ensure compatibility.

Q4: What maintenance does a typical motorized decoiler require?

A4: Regular maintenance includes checking and greasing bearings, inspecting hydraulic systems for leaks, verifying the condition of the mandrel segments and expansion mechanism, and ensuring electrical connections and motor drives are clean and tight. Following the manufacturer's (such as SANSO) preventative maintenance schedule is essential for long-term reliability.

Q5: Is the investment in a motorized decoiler justified for a smaller tube mill?

A5: The justification depends on production volume, material value, and quality demands. For smaller mills running lighter gauges or lower volumes, a simpler decoiler might suffice. However, if you are experiencing quality issues from uneven feed, seeking higher line speeds, or processing more expensive/pre-finished materials (like painted or stainless steel), the ROI from a motorized decoiler through reduced scrap and higher throughput can be very compelling, even for smaller operations.