Every welded pipe or tube you see starts as a coiled strip of metal. But before that strip can be formed, welded, and cut, it needs to be properly prepared. This is where a decoiler and straightener come in.

These two machines form the critical first stage of any modern tube or pipe mill. Their job is simple but vital: to unwind the metal coil and then remove the internal curvature or "coil memory." This creates a perfectly flat, consistent feed of material for the forming and welding stations. It's a process that directly impacts final product quality, material yield, and overall line efficiency.

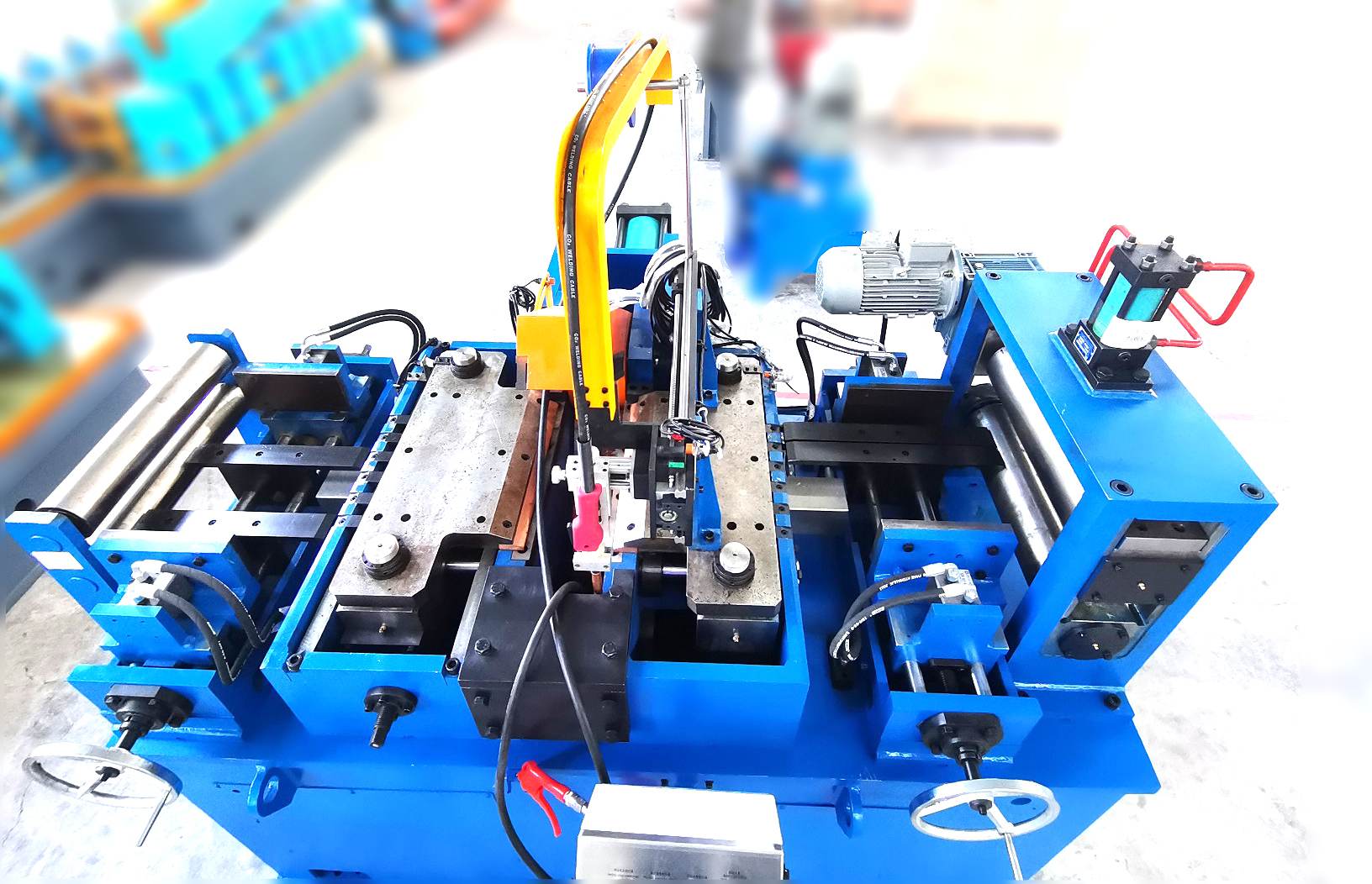

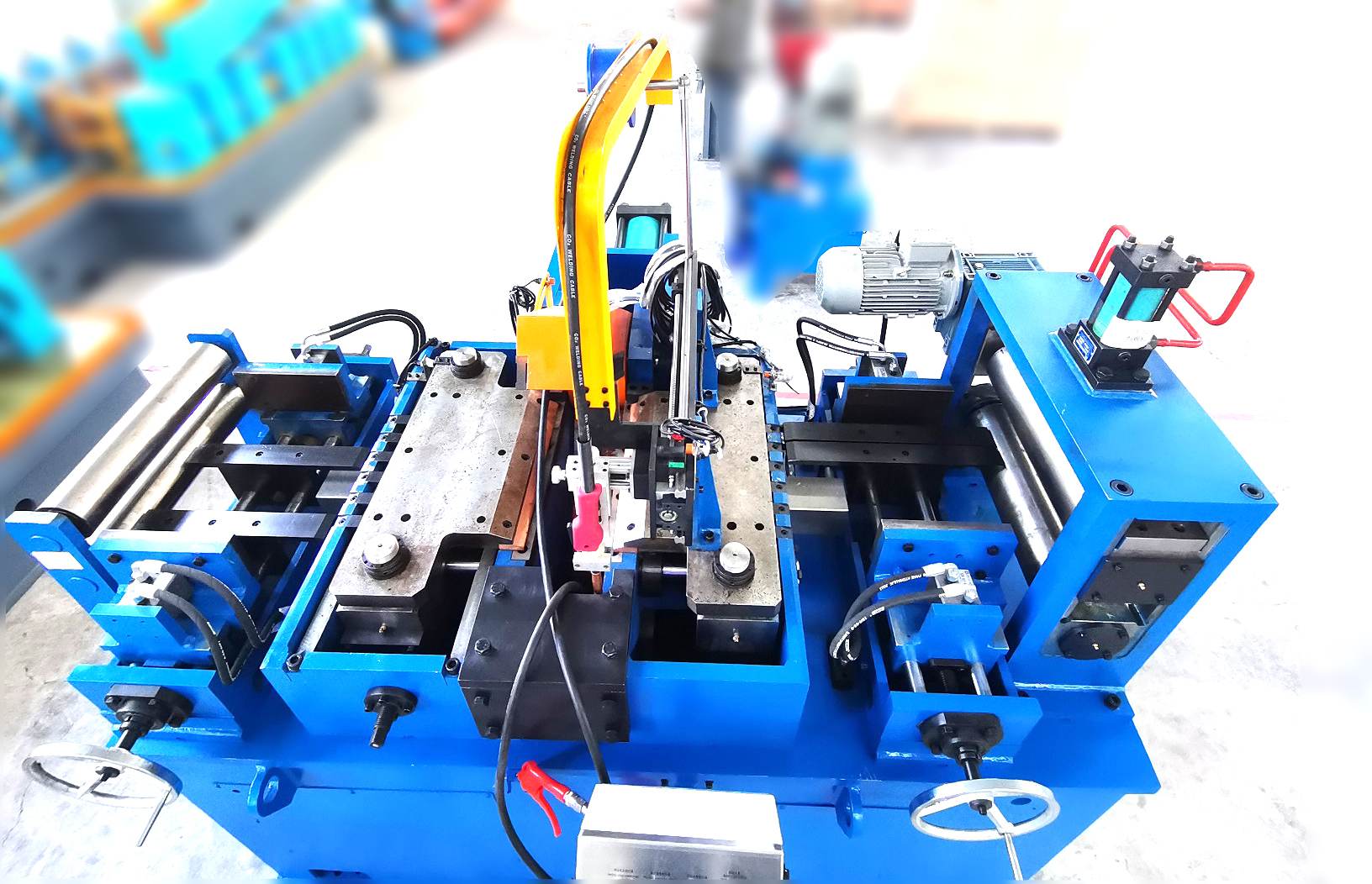

Leading manufacturers like SANSO specialize in designing integrated decoiler and straightener systems. These are built to meet the high demands of international tube production, ensuring reliability from the very first step.

Let's break down this key piece of equipment. A decoiler and straightener is often a combined unit or two tightly synchronized machines at the head of a production line.

The decoiler, sometimes called an uncoiler, is the component that holds and unwinds the heavy metal coil. It uses a motorized mandrel that expands to grip the coil's inner diameter. A controlled braking system manages the payout speed and prevents the coil from unraveling uncontrollably.

The straightener, or leveler, is mounted directly after the decoiler. It consists of a series of staggered rollers, typically arranged in multiple rows. As the curved metal strip passes through these rollers, it undergoes a bending process that reverses the coil memory. The result is a flat, straight strip ready for precision forming.

The synergy between these two components is what makes the system effective. Their operation is a continuous, coordinated dance.

First, a crane places the metal coil onto the decoiler's expanding mandrel. The leading end of the strip is then manually or automatically fed through the straightener's rollers. Once threaded, the main line drive pulls the material.

As the strip is pulled, the decoiler's brake provides back tension. This tension is crucial. It keeps the strip taut between the decoiler and the straightener, preventing loops or snags. It also helps the straightener rollers work more effectively.

Inside the straightener, the adjustable upper roller bank applies precise pressure. Operators set this based on material thickness, width, and yield strength. The rollers progressively flex the metal beyond its yield point, permanently eliminating the curvature. The output is a flat strip.

You cannot make a high-quality welded tube from a wavy or irregular strip. The decoiler and straightener stage sets the foundation for everything that follows.

A poorly leveled strip causes immediate problems in the mill's forming section. The edges won't align correctly in the fin pass stands. This leads to inconsistent weld closure, forcing the high-frequency welder to work harder. The result can be weak welds, porosity, or even splits.

Dimensional consistency also suffers. A strip with residual curl will not form a perfectly round tube. You get out-of-round sections and inconsistent diameters. This leads to scrap and failed quality inspections.

Furthermore, an unsteady feed from an un-synchronized decoiler and straightener causes speed variations. These fluctuations can create "weld chatter" marks on the pipe's surface. They also make the cutting saw's length control less accurate, causing end waste.

Not all entry-level equipment is created equal. For high-volume or precision tube making, specific features are non-negotiable.

A mandrel-less decoiler design is gaining popularity for its speed. It uses hydraulic arms or cones to support the coil from the outside, eliminating the time needed to expand a mandrel through the core. This is key for quick coil changes.

The straightener roller configuration is vital. More rollers (9, 11, or 13-roll configurations) provide a gentler, more effective leveling action. They handle high-strength materials and thicker strips better than simple 5-roll units.

Independent DC or servo drive systems on the decoiler mandrel are essential. They allow for precise digital tension control (DPI - Digital Payoff Interface), synchronizing perfectly with the line speed. This replaces old-fashioned mechanical brakes that wear out and are inconsistent.

Heavy-duty construction matters. These machines handle tons of metal. The frame, roller shafts, and bearings must be oversized to resist deflection and wear over years of service. Brands like SANSO focus on this robust construction to minimize long-term maintenance.

Selecting a decoiler and straightener isn't a one-size-fits-all decision. You need to match the machine to your production profile.

First, consider your material specifications. What is the maximum and minimum coil width, thickness (gauge), and weight you will process? What is the material's yield strength (e.g., mild steel vs. high-strength steel)? The machine must be rated for these values.

Next, evaluate your required line speed. A decoiler and straightener for a 30-meter-per-minute line is different from one for a 120-meter-per-minute line. The straightener rollers must rotate at the correct surface speed without causing burnish marks.

Floor space is another practical concern. Combined units save space, while separate machines might offer more flexibility for custom layouts. Consider how the coil loading area will work in your shop.

Finally, think about automation. Do you need semi-automatic threading? What about a coil car for easier loading? Planning for future automation during the initial purchase can save major costs later.

A well-maintained decoiler and straightener prevent unplanned downtime. Here are some practical tips.

Lubricate according to schedule. The straightener roller bearings operate under high pressure. Regular greasing is their lifeline. Check the decoiler mandrel expansion mechanism weekly for smooth operation.

Inspect and clean rollers daily. Metal dust and debris can embed into the straightener rollers, causing surface marks on the strip. Use a non-metallic brush or cloth to clean them. Look for signs of scoring or wear.

Check hydraulic and pneumatic systems. If your decoiler uses hydraulic mandrel expansion or lift tables, check for leaks and proper fluid levels. Ensure air lines for brakes or clutches are not leaking.

Monitor the alignment. Over time, vibration can shift the straightener's entry and exit guides. A misaligned strip will wear rollers unevenly and affect leveling quality. Perform alignment checks monthly.

Keep a log of settings. Record the straightener roller adjustments (gap, pressure) for different materials. This reduces setup time and scrap when switching between jobs.

Technology is making this foundational stage more intelligent. The goal is to move from reactive to predictive operations.

Integrated laser scanners can now measure strip flatness as it exits the straightener. This data is fed back to a PLC, which can automatically adjust the roller pressure in real-time for perfect flatness, regardless of minor material variations.

Remote monitoring is another trend. Service technicians from a company like SANSO can securely access machine performance data. They can spot trends indicating a bearing is warming up or tension is drifting, recommending maintenance before a failure stops the line.

These smart systems turn the decoiler and straightener from a simple preparation stage into an active quality control checkpoint. They ensure the mill is fed perfect material, boosting overall equipment effectiveness (OEE).

The decoiler and straightener may not be the most glamorous part of a tube mill, but they are arguably the most important for consistency. Investing in a robust, well-designed system from the start pays dividends every day in reduced scrap, fewer weld defects, and higher throughput. It’s the unsung hero that guarantees the raw material is flawless before the complex work of forming and welding even begins. For manufacturers looking to compete on quality and efficiency, prioritizing this first stage with reliable technology from proven brands like SANSO is a fundamental step.

Q1: Can I use a decoiler without a straightener in my tube mill?

A1: This is not recommended for producing quality welded tube. A coil has inherent curvature (coil set). Feeding a curved strip directly into the forming rolls will cause misalignment, poor weld closure, and out-of-round tubes. The straightener is essential for removing this memory and creating a flat blank.

Q2: How often do the straightener rollers need to be replaced?

A2: There's no fixed timeline. Roller life depends on material processed (abrasive high-strength steel wears them faster), line speed, and maintenance. With proper cleaning and lubrication, rollers can last years. Replacement is typically needed when surface scoring or wear marks begin to transfer to the material surface.

Q3: What causes vertical waves (ripples) in the strip after it leaves the straightener?

A3: This is often called "edge wave" or "center buckle." It's usually a sign of incorrect straightener adjustment. If the rollers are set too tight for the material, they can over-stretch the center. Conversely, incorrect alignment or worn rollers can cause uneven leveling. The adjustment needs to be precisely calibrated for the specific strip width and thickness.

Q4: We process different coil widths daily. Is changing the straightener guides difficult?

A4: On older machines, it can be time-consuming. Modern decoiler and straightener systems feature quick-adjust, tool-free side guide mechanisms. Operators can often slide guides to a new width in seconds using hand wheels or levers, minimizing changeover downtime.

Q5: Why is controlled tension from the decoiler so important?

A5: Consistent, controlled tension is the "glue" that synchronizes the decoiler and straightener with the rest of the mill. Too little tension causes a loose loop that can jam or scratch the material. Too much tension can over-stress the strip, cause it to narrow (neck), and put excessive load on the straightener drives. Precise tension ensures a smooth, steady feed critical for welding and cutting accuracy.